YesWelder Firstess DP200 Review - Multi-process MIG Welder With Pulse and Dual Pulse

Welding has evolved from a highly specialized industrial profession to a hobby and DIY work many enjoy at home. The new inverter welders, which are easy to use, set up, and reasonably priced, made this change possible.

Today, we will discuss the perfect example of a welder that both new welders and professionals can enjoy—the YesWelder DP200. We designed this machine to provide enough versatility and ease of use for beginners, as well as some advanced features and control options best suited for seasoned welders.

Without further ado, let's check what YesWelder DP200 has to offer.

YesWelder Firstess DP200: Multi-process MIG Welder With Pulse and Dual Pulse

YesWelder Firstess DP200 is the new welding machine in our lineup of budget-friendly machines, designed for both beginners and professional welders. DP200 is primarily a MIG welder with added Flux-cored, Stick, and DC TIG welding functions, allowing you to weld steel, stainless steel, or aluminum.

What makes the Firstess DP200 a unique welding machine on the market is its intuitive interface with a large 7” LCD screen and fully adjustable MIG welding process. Like advanced TIG Welders, DP200 allows you to adjust pre-flow, hot start, ramp-up, ramp-down, and post-flow, but this time, in MIG welding.

In addition, you can control the pulse and dual pulse (pulse-on-pulse) MIG, which makes it perfect for seasoned welders. Pulsed MIG is ideal for anyone looking for the highest quality and aesthetics welds, especially on aluminum and other heat-sensitive metals.

But don't be intimidated. The DP200 has smart settings to help beginners and new welders get a head start. All the options provide the perfect balance between ease of use and industrial-grade controls, but there is more.

Firstess DP200 Multi-process MIG Welder With Pulse and Dual Pulse

Technical Specifications

|

Processes |

MIG, Flux Core, DC Lift TIG, Stick |

|

Input Power |

120V/240V |

|

Phase |

1-Phase; 50-60 Hz |

|

Output Power (240V) |

MIG/Flux core: 30-200 A TIG: 10-200A Stick: 10-180A |

|

Output Power (120V) |

MIG/Flux core: 30-140 A TIG: 10-120 A Stick: 10-120 A |

|

Duty Cycle (240V) |

25% at 200A 60% at 130A |

|

Duty Cycle (120V) |

25% at 120A 60% at 78A |

|

Weldable Materials |

Mild Steel Stainless Steel Aluminum (MIG only) |

|

Spool Gun |

Compatible, Not included |

|

Heat Control |

Pulse and Dual Pulse MIG |

|

Control Options |

Manual Smart Advanced Controls |

|

Memory |

Up to 50 presets (MIG/MAG) |

|

System Adaptability |

Fully Upgradable Software |

What Do You Get For The Money Spent?

At YesWelder, we understand how vital welding accessories are. That's why DP200 comes with everything you need to weld straight out of the box, including the MIG torch, Stick electrode holder, 120/240V adapter, gas hose, graphene liner, different drive rolls, and a few spools of wire. All accessories come with durable but flexible heavy-duty cables that are built to last.

What does the DP200 come with?

The package includes all the accessories that are ready to install and use. So, it will take no time to unbox everything, plug it in, and start welding. The front panel has clearly marked ports for positive and negative terminals, the TIG pedal, and the spool gun, so you can’t do too much wrong.

If DP200 is your first welder and you have no idea how to set it up, do not be afraid. Just hit the help button on the front panel, and you can find everything you need to know about it, including the setup diagram for different processes, control explanations, specifications, recommended accessories, and troubleshooting. So, instead of looking for an instruction manual, you have all the help incorporated into your welder.

Large LCD Screen With IntuiWeld™ Interface Of YesWelder DP200

One of the first things that grab your attention when you look at YesWelder DP200 is a large, 7" LCD display, which is amazingly intuitive, colorful, and easy to use and understand. Although some older welders are not fans of digital displays, this one is extremely user-friendly and provides the ultimate operating experience.

The display is tilted at 15 degrees, has a multi-angle view, and displays large numbers. You can effectively see the displayed settings, suggestions, and cautions anywhere. With 280 nits, adjustable brightness, and dark and light themes, you can use and clearly see the display in broad daylight or dark workshops. But that’s not all.

The more settings the welder has, the more intimidating it can be for beginners. So, to make welding operations even more convenient for beginners, we paired the large screen with the IntuiWeld™ interface (copyright registration pending).

Navigating through the unit interface (UI) is straightforward and well-illustrated, and there is an info panel that explains everything. You navigate through the options by using the central knob or two help knobs.

The interface involves selecting the welding process you wish to use. Next, you can use smart mode (choose the gas, wire type, diameter, material, etc.) to get the recommended current and voltage for the given welding application or set the parameters manually. Seasoned welders can access the advanced settings menu, which we will explain further in the text.

The large display can also show errors, such as overheating or lack of gas, to make troubleshooting as easy as possible. You can also run a check prior to welding to make sure everything is well connected and works. Settings mode inside the interface allows you to use an imperial or metric unit system, adjust brightness, or change a theme.

System Upgradeability

Although the amount of information, control, and parameters you get makes DP200’s UI one of the most intuitive, easy-to-use, yet detailed interfaces on the welder's market, that’s not all. Like much more expensive, industry-grade machines, the DP200 has a USB port, which allows you to install new software updates and keep your work up to date.

The entire machine software is fully upgradable, meaning you will receive upgrades over time. Upgrading the software is a much more convenient way of answering the user’s feedback and adding features than remaking and having to buy a newer version of the machine.

The Power Of YesWelder Firstess DP200

The Firstess DP200 is a dual-voltage welder rated at a maximum of 200 amps. Dual voltage means you can plug it into a regular 120V household outlet in your garage or a dedicated 240V shop outlet for maximum power.

At 240V, the welder reaches a maximum of 200 amps, which is suitable for metal up to 3/8" thick. At 120V, you get a maximum of 140 amps, so you can weld up to 1/8" steel, which is more than enough for many household applications. For the lower end, you can weld thin metals down to 24 ga, including mild steel, stainless steel, and aluminum.

The DP200's welding capability and amperage range make it perfect for most hobby and home applications. Some examples are welding metal gates, autobodies, aluminum boats, farm tools, DIY and hobby projects, or garden tools and metal gates.

Firstess DP200 Welding Processes

YesWelder DP200 is primarily a MIG welder, but it also provides Flux-cored Arc Welding (FCAW), Stick welding, and TIG welding options. This versatility and flexibility make it ideal for most welding applications.

MIG welding (GMAW): Gas Metal Arc Welding or MIG welding is the primary welding process of DP200. As noted, you can use smart mode or manually set up each part of the MIG cycle. In addition, you can utilize pulse or dual pulse MIG and weld mild steel, stainless steel, or aluminum.

Flux Cored Arc Welding (FCAW): Flux core welding is a variant of MIG welding that uses a self-shielded, flux-cored wire. As a result, you don't need a shielding gas, which makes it perfect for outdoor repairs and applications. To use it, switch the process in the main menu, polarity on the front panel, and wire and wire drive rolls inside the wire compartment.

TIG Welding (GTAW): DP200 features the basic variant of TIG welding—the DC lift TIG. The lift start is a good option if you need to TIG weld some steel around the house, and the welder also supports the foot pedal with automatic recognition. Since this is a DC-only welder, you cannot TIG weld aluminum with it.

Note: The TIG torch or foot pedal are sold separately.

Stick welding (SMAW): Stick/Arc uses flux-coated electrodes, which make it perfect for most outdoor repairs, including equipment for farm and ranch applications. Stick welding with DP200 is smooth, with a stable arc and reliable arc starts. You just need to plug in the supplied holder and adjust the polarity based on the electrodes you are using.

Manual Control Vs. Smart MIG

The YesWelder DP200 is a fantastic welder for both beginners and seasoned welders. The primary reason is the balance between manual control and intelligent smart options.

Smart options are perfect for any beginner who needs a head start in welding. To use them, you need to select the shielding gas (pure CO2, argon, or argon CO2 mixture, etc.), wire type (steel, stainless steel, or aluminum), and wire diameter (.024" - .045"), as well as the thickness of the metal you are about to weld (24 ga up to 3/8"). The welder then gives you the recommended wire feed speed and voltage, which is good enough to produce solid welds.

Manual options: While synergic or smart options will give you a head start, most experienced welders like to fine-tune their machines. If you feel like your wire feed speed or voltage is running a bit hot or cold, you can manually adjust it by using one or two knobs and tailor the settings for your applications.

Advanced MIG Controls

The DP200 goes even further and allows you to access the advanced options menu. In the advanced options menu, you can adjust the following:

- Pre-flow: It lets the shielding gas flow before the arc starts, purging out the air buildup and providing better shielding to the weld puddle.

- Inductance: The inductance adjusts how fast the arc reaches the base amperage in short-circuit MIG. Increasing the time creates a gradual increase of amperage, reducing the spatter, heat buildup, or heat stress on heat-sensitive metals.

- Start amps (Hot start): Delivers a boost of amperage at the start of the weld, allowing the base piece to be preheated right at the beginning of the weld.

- Start slope: Dictates the time the current takes from start amps to welding amps.

- Crater amperage: A crater is a welding defect in the form of a hole that forms at the end of the weld. With crater amperage, you can reduce the current at the end of the weld. This way, you can spend more time at the end of the weld and fill the crater without burning through the end of the weld.

- Crater slope: This parameter sets the time it takes the current to drop to the crater amperage from the welding amperage.

- Burnback: This feature activates as the arc stops. The welding wire retracts back into the welding gun, preventing it from sticking to the nozzle or workpiece.

- Post-flow: It lets the shielding gas flow for a few seconds after finishing the weld to provide proper protection and promote torch cooling.

Trigger Controls and Memory Options

- Trigger controls - 2T/4T: Adjusts the number of trigger touches required for welding. In 2T, you hold the trigger and weld, while in 4T, you press and release to initiate the welding and press and release the trigger to terminate welding. There is also an advanced S4T, or unique 4T option, that unlocks most of the controls we discussed above.

- Spot: Allows you to make repetitive tack welds across larger joints and parts to keep them in place.

If you found a sweet spot and loved how your welds turned out, you can save the current controls. DP200 offers up to 50 memory settings (MIG/MAG), allowing you to make repetitive welds each time.

You can add notes for each memory setting, allowing you to reuse them in specific situations and applications. This can be particularly useful for beginners who spend a lot of time exploring and dialing in the settings that feel right for them.

Pulsed and Dual Pulsed MIG Welding

Pulsed welding is finding more use in everyday welding, but in the past, it was reserved for TIG welding. In MIG welding, pulse options were found in state-of-the-art industrial-grade welders since it was hard to pull off, and the equipment was expensive.

But today, that's not the case. We are allowing welders to use pulse and DualPulse™ (pulse on pulse) options with our reasonably priced MIG welder - YesWelder DP200.

Pulse welding has become a must-have option for anyone welding thin or delicate metals that are prone to burn-through or distortion. Pulsing between the base amperage and background amperage provides excellent heat control and reduces heat buildup and spatter on the pieces.

But we went even further by introducing another pulse that turns the first pulse on and off. Dual pulsing provides even better welding results and produces TIG-like welds in the form of stacked dimes.

Dual Pulse MIG Welds Using the DP200

Photo by @weldsbyzen (TikTok)

Pulsing On YesWelder Firstess DP200

The pulsed MIG option is synergic within the DP200. The welder automatically adjusts the wire feed speed and voltage to resist the oscillations between the base and background amps and provide a stable arc throughout the process.

The pulse-on-pulse, or DualPulse™ on Firstess DP200, is highly customizable and advanced. You can adjust the various aspects of the pulsing, such as:

- Base amperage: The primary amperage option, or the peak amperage on the upper side of the cycle.

- Background amperage: The lower end of the pulse cycle that current oscillates during the pulsed welding.

- Pulse Frequency: The frequency setting shows how fast or slow you want the pulses to be. For example, 1 Hz means one pulse per second, so the pulsing completes in one second.

- Pulse duty cycle: The duty cycle states how much time the pulse spends in the base and background current. At 50%, this time is equal. A 30% cycle means the current spends 30% on base amps and 70% on background amps, and vice versa.

MIG Welding Aluminum With DP200

Pulsing on DP200 is perfect when you need to MIG weld aluminum. With pulse, you can avoid most issues with heat buildup on the aluminum, including the burn-through or spatter.

Adjusting the dual pulse or pulse on the pulse with DP200 allows you to achieve TIG-like welds on aluminum. This feature lets you create the stacked dimes look characteristic of TIG welding. Stacked dimes are highly aesthetic and best suited for applications that require excellent weld appearance.

To MIG weld aluminum with YesWelder DP200, you will need to insert the graphene liner and drive rolls for aluminum wire. Luckily, both come in the package, so you can weld aluminum straight out of the box. The rolls will provide a smooth feed of the soft aluminum wire, and the graphene liner will prevent it from clogging through the liner.

Alternatively, many find MIG welding aluminum much more convenient with a spool gun. The DP200 is spool gun compatible, but you will need to buy it independently. You can check the list of compatible equipment inside the welder's help interface.

The YesWelder DP200 Build

At YesWelder, we provide excellent quality control and ensure our machines are built to last. The DP200 perfectly balances a modern look and durability. The digital display provides a contemporary appearance, while the case is sturdy.

The unit has a dual fan for better heat dissipation. The fan has variable speed, so it is quieter before welding and speeds up once the temperature rises during welding. In addition, fans provide better cooling, which increases the overall duty cycle. The unit has built-in overheating protection that turns the welder off to protect the internal components from damage.

YesWelder DP200 has a well-built wire compartment. The compartment can fit up to 10-pound wire spools, reducing the need for frequent wire changes. The full metal wire feed mechanism is reliable and fully adjustable. It allows you to change the rolls and adjust the tension quickly to provide smooth wire feed. The package includes both knurled rolls for soft flux-core or aluminum wire and groove rolls for solid wire.

The best part is the small storage compartment at the bottom. You can use it to store the drive rolls you are not using and MIG torch tips to reduce the replacement downtime and increase productivity. The USB port is at the top of the compartment, and you can use it to upgrade your software.

Is YesWelder DP200 Worth The Money?

With a regular price of $699, the value YesWelder DP200 provides for the money spent is fantastic. As part of a Kickstarter campaign, you can get it even cheaper, so hurry up and grab it at an unbeatable low price.

For the money spent, you get a MIG welder with Stick, Flux core, and TIG capabilities, as well as industry-grade features such as pulse and dual pulse, a large LCD display, memory options, software updates, and more. This welder provides a perfect balance between ease of use, intuitive settings, and advanced controls. Smart settings are ideal for new welders, while advanced controls and options suit seasoned welders.

We strongly recommend it to anyone new to welding, a welding enthusiast, or a DIY lover. But it's also perfect for a seasoned welder looking to get TIG-like results on aluminum with an MIG welder. Its features can match those of some industry-grade welders, while the price matches the budget-friendly market. As a result, the value you get for the money spent is unmatched in today’s welding machine market.

We strongly recommend it to anyone new to welding, a welding enthusiast, or a DIY lover. But it's also perfect for a seasoned welder looking to get TIG-like results on aluminum with an MIG welder. Its features can match those of some industry-grade welders, while the price matches the budget-friendly market. As a result, the value you get for the money spent is unmatched in today’s welding machine market.

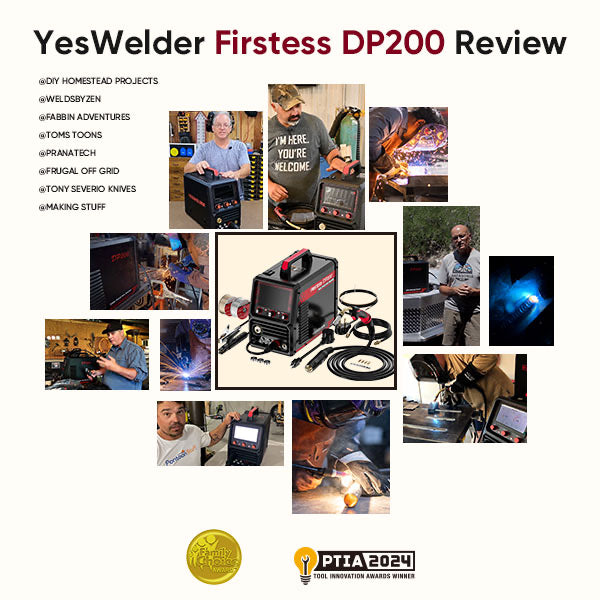

Search YesWelder DP200 and discover more DP200 review videos on YouTube:

@Allen's welding/woodworking, @Fabbin Adventures, @DIY Homestead Projects, @donyboy73, @Tony Severio Knives, @Zen, etc.

👏 You may be interested in the following:

- Welding Parameters Explained

- Pulsed MIG Welding Tips And Techniques

- How To Reduce Excessive MIG Welding Spatter

Leave a comment