MIG, Pulsed MIG, and Double Pulsed MIG Explained

The MIG welding process works great for thin sheet metal and thick materials. It’s relatively easy to master and can be used in almost all welding applications.

But, regular short circuit MIG transfer and even spray MIG transfer are limited. That’s why new technologies constantly emerge to improve and break the welding boundaries.

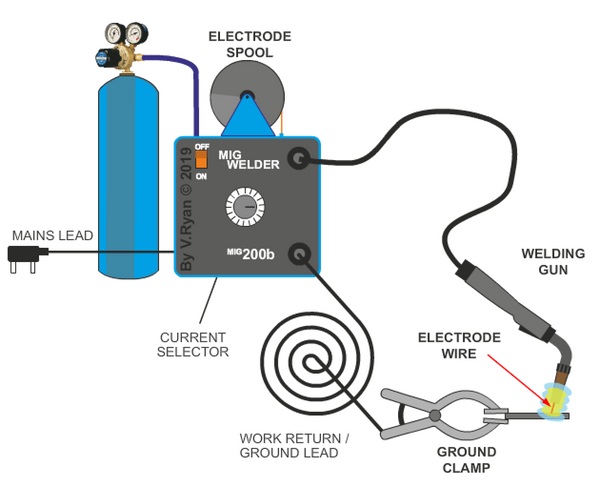

Source from https://technologystudent.com/despro_flsh/mig1.html

How MIG Welding Works in Short

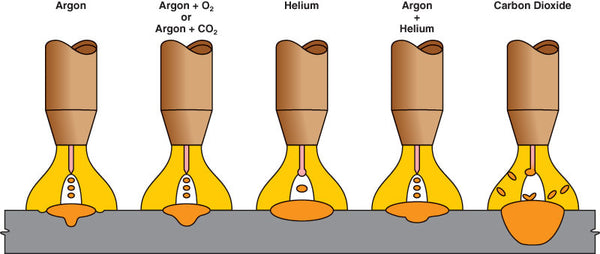

The MIG welding process relies on a constant voltage power source and an automated wire feeder. These two are typically combined in small inverter-based welders. Additionally, MIG welding requires a shielding gas. For welding steel, argon and carbon dioxide mixtures are most commonly used, while MIG welding aluminum requires 100% argon.

That much you probably already know.

Source from http://www.halversoncts.com/711-gmawfcaw-shielding-gases.html

But, do you know the differences between spray and short circuit transfer?

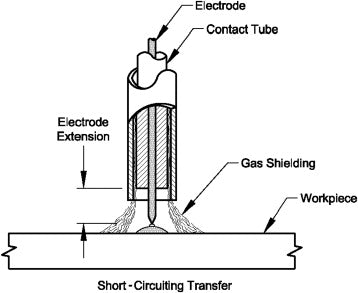

Short Circuit MIG Transfer

Short circuit transfer deposits filler metal into the weld pool by melting the MIG wire at the point of contact between the tip of the wire and the welded metal.

Essentially, the wire short circuits with the grounded metal (ground clamp is attached to it) and closes the electric circuit. As a result, the resistance of electrical current flow melts the wire, and the liquefied metal flows into the weld pool. Next, the wire feeder pushes more wire through the MIG gun, and the wire tip again short circuits, repeating the process over and over again many times per second.

Source from https://www.sciencedirect.com/topics/engineering/short-circuiting-transfer

This works well for most DIY or even professional jobs. But, short circuit transfer is messy. Every time the wire short circuits, it creates spatter.

Still, there are numerous advantages of short circuit transfer. You can use it to weld in all positions and all steel thicknesses. Not bad for the simplest, standard MIG welding mode.

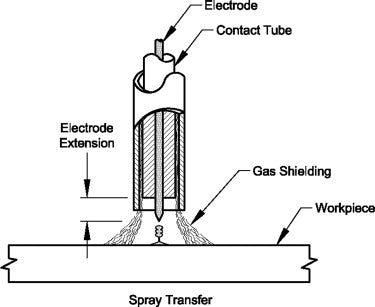

Spray MIG Transfer

Spray transfer doesn’t cause spatter and achieves an exceptionally high weld metal deposition rate. Plus, you can weld quickly and create deeply penetrating welds.

The spray transfer arc never cuts out once established. Unlike with a short circuit, the filler metal is deposited in tiny droplets that “spray” from the wire’s tip to the welded metal. But, the wire never touches the base material; it melts at a distance into these tiny droplets of metal.

Source from https://www.sciencedirect.com/topics/engineering/short-circuiting-transfer

To achieve spray transfer when MIG welding, you must simultaneously crank up the wire feeding speed and the voltage output to higher values than for short circuit MIG. Additionally, you must use an Ar/CO2 mixture with at least 90% argon for quality spray mode.

Plus, it’s necessary to utilize spray transfer to MIG weld aluminum because short circuit transfer creates poor results.

So, spray transfer has all these advantages. There must be a catch.. Right?

Yes.. Unfortunately, there is. Spray transfer only works in horizontal and flat positions because the weld puddle is too fluid and can fall on you if making out-of-position welds. Plus, it’s very challenging to use spray transfer to weld vertically uphill.

So.. What is the solution to this issue?

Pulsed MIG Welding

The pulse MIG welding process combines the best of both worlds, so to speak. It achieves the spray transfer mode, with all its benefits, but it also welds vertically and in overhead positions.

How? — you may ask.

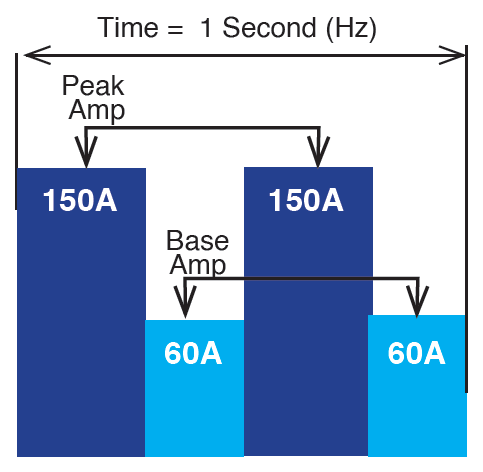

Well, the current pulses, or alternates, between two values: peak current and background current. The peak current is your typical high amperage, high wire feeding speed and voltage that achieve spray transfer. The background current is lower in intensity and allows the puddle to solidify faster, giving you more control.

So, the peak current behaves just like the spray transfer, while the background current keeps the arc established and backs off the heat from the puddle. This pulsing action happens tens or hundreds of times per second, depending on the settings on your MIG welding machine.

Pulse Frequency

Source from https://unimig.com.au/pulse-or-no-pulse-when-and-why-you-should-pulse-weld/

An additional advantage of pulse MIG welding is heat control. Since half of the pulse uses low current, it’s easier to avoid burning through or warping thin gauge metal. Plus, the puddle itself is more stable and easier to manage.

So, on top of the deep penetration, low to no spatter, fast travel speed, and high deposition rate, it’s easy to manage the arc and reduce warping and burning through.

Single pulse MIG welders are often employed in stainless steel and aluminum applications, where out-of-position welding is performed. Additionally, in auto repair shops, MIG brazing with silicon bronze works far better with pulse MIG welding.

Photo by @russianweldersteam

Dual Pulse MIG Welding

If pulsed MIG is good, the dual pulse (double pulse) MIG must be much better. Right?

Well, it actually is. Dual pulse MIG is capable of producing TIG-like welds. Exceptionally good-looking, shiny, and clean — especially on aluminum. It has all the same benefits as single pulse MIG welding. But it also provides slightly better heat control and allows you to create that stack of dimes appearance associated with TIG.

Dual pulse, sometimes also called pulse on pulse (“PoP”), adds another layer of pulsing into the waveform. So, you have two pulse currents that alternate, and each has its own peak and background currents.

Image of double pulse MIG diagram.

Source: https://www.weldclass.com.au/blog/94-what-is-a-pulse-mig-a-how-why-guide-to-pulse-mig-welding

This additional pulse allows the formation of the stack of dimes appearance. Since there are two different waves of pulses and each has a significant difference in current, each of the two pulses can alter the appearance of the weld. With some practice, it’s easy to learn how to replicate the TIG-like weld look.

But, unlike TIG, the MIG welding process allows far higher welding speeds, especially in spray transfer mode that’s native for pulse MIG welding.

The Synergic Pulse and Dual Pulse MIG Welding

The welding industry still hasn’t fully adapted to the pulse MIG technology. So there are numerous differences between pulse MIG machines among brands. Even the names of functions that are a part of the pulse settings are often differently called.

The pulse MIG settings are very complex, and a single mistake can render this technology useless. There are primary and background amps, voltage, and wire feeding speed, pulse frequency, pulse balance, arc length, start and ending current, and other settings.

The sheer number of adjustments and the lack of industry standards prompted many manufacturers to design pulse MIG welders with synergic modes. This mode typically uses the best settings tested by the manufacturer and allows you to manually set only a few parameters.

YesWelder Firstess DP200 DualPulse Aluminum MIG Welder

This is good from the user’s perspective. Since pulse MIG can easily take a turn for the worst, you don’t have to worry about the weld quality. Just input the base amps and fine-tune the voltage output and you are all set. Or at least, that’s what many brands offer.

Conclusion

Pulse MIG improves welding productivity and final weld quality. But, most people don’t need these advanced MIG welding features. Still, if you make out-of-position welds or want maximum, TIG-like weld quality, getting a dual pulse MIG-capable machine may be worth considering.

If you liked our explanation of pulse MIG functionality, please share it with your friends. The more people know how welding technology advances, the sooner we’ll see industry standards change and favor new technologies.

However, pulse MIG welding machines are expensive. So, just remember that if you are a hobby welder, you don't need to invest in this technology. Standard MIG does a great job unless you run a high-end welding shop. Eventually, these machines may cost less. But, for now, a beginner welder or a professional that doesn't need maximum MIG weld quality is unlikely to benefit from buying such expensive machines.

Not a problem! We’re happy to know that this helps you. :)

Thanks for explaining MIG. Now I see it has various types like pulsed, double pulsed.

WelderReview.com

I have been in the welding Business for 40yrs. I have seen most processes and welded Bikes to Aircraft!!

Your people are “RIGHT ON” explaining the process. This type of welding must be mastered for us to stay on top of the manufacturing envelope. I believe all welders need to know this knowledge! knowing what process to use and proper fit up of the weld joint. is essential for the weld to hold and serve a life time of service. If you know about welds. The weld is so-pose to be stronger than the base metal that it is joining. Knowing when to use (GOBBLER – SPRAY TRANSFER OR PULSE * DOUBLE PULSE ) is the question?#&* I myself am going to purchase several Yes welding machines to add to my inventory. to choose from. its your choice! be part of the usual or be on top of your game. Having very few welding competitors will make you financially untouchable, have a long list of clients.

thank you

MR RPM

ca.#876283

Nice article and a good explanation of a newer complex process. I’ve been thinking of getting a double pulse welder for about a year. The single/ double pulse machines that I’ve looked at also come with a-synergistic program that enables you to take advantage of this technology and mainly fine tune by adjusting voltage 3 to +3. A few days ago, you sent me an article/advertisement about pulse welding and your ywm 211p, which once again piqued my interest.. Lol, who am I kidding, You’ve really tempted me. I have tried to find a user review of your machine on line but can’t seem to find one. I know it’s a new product, but do you have a link you can share or can you direct me to a review??

This is amazing technology that I have never heard about. My son owns a Motorsport Dealership and has to weld aluminum and steel at times. He sells and services Snowmobiles, Motorcycles, 4 wheelers, Side by sides, Aluminum Trailers, etc,,,. I feel so much more educated about welding technologies !! Thank you. Craig

Leave a comment