What Do Colors Mean in Welding

In the realm of welding, colors serve as silent indicators, revealing crucial information about the welding process. Beyond the sparks and protective gear, understanding the significance of colors in welding unveils a hidden language that welders decipher with each flicker of light.

From the vibrant hues of the welding arc to the subtle transformations in the heated metal, this article explores the spectrum of colors in welding and their implications. Understanding what do colors mean in welding is crucial in achieving the strongest and highest quality results.

Different Colors in Welding

Source: https://technoweld.com.au/2019/06/03/why-do-we-use-colour-in-welding/

Why Does Steel Change Color When Heated?

Metals change color for various reasons, but the common cause is heat. As the metal is heated, it reacts with the atmosphere, so the molecular structure changes, creating a very thin oxidation layer. Each level of heat creates a different depth of oxidation that will reflect a specific wavelength of light and absorb all other wavelengths.

As a result, we see colors, which vary based on the atmosphere's composition, the temperature at which they meet, and the time the metal is exposed at the elevated temperature. Very vivid colors in the metal can be beautiful, but when it comes to the weld's strength, they are not a good sign. In nature, vivid colors signify danger; the same rules can apply in welding.

Weld Colors Explained

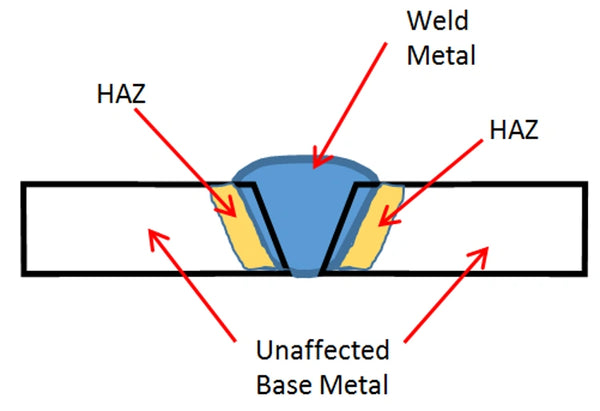

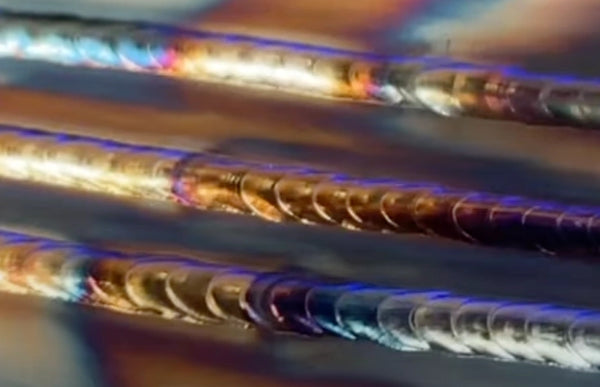

The two pieces and the filler metals are heated to a high temperature during the welding, creating a specific heat-affected zone (HAZ). If heated steel reacts with the gases in the atmosphere, it creates an oxide layer, which, once again, results in colored welds. The colors appear in a predictable pattern, from chrome to straw, gold, blue to purple.

To fight with colorful welds, welders use shielding gas. An inert gas, such as Argon or Helium, protects the molten metal from atmospheric contamination, avoiding oxidation, corrosion, porosity, and more. In Stick and Flux core welding, a layer of flux does the same. It helps metal retain corrosion resistance and coloring of mild steel or hardened steel pieces. Colors are also known as heat tint, even though we already explained they don't appear only due to heat.

Are Colors In Welding Good?

This depends on the specific application of welding. For example, for welding artists like Josh Welton from Brown Dog Welding, colors are something everyone desires. Colors give metal art, such as paintings or sculptures, beautiful vibes, and it is something everyone wants to reach.

Credit to Josh Welton from Brown Dog Welding

However, in critical applications, such as pharmaceutical or other sanitary welding situations, anything over chrome or, in specific cases, a light gold color is unacceptable. Even the thinnest oxidation can affect corrosion resistance and create weak spots vulnerable to rust. Meanwhile, shades up through light blues are allowed in other sanitary welding situations. Light colors mean thin surface oxidation that can be removed, and corrosion resistance is quickly restored.

So, colors in the weld are not an absolute foolproof indicator, but they can be a pretty good marker of a weld's strength. As the heated steel meets the contamination, it shows colors, so if you want critical results, avoid colors.

Color Scale

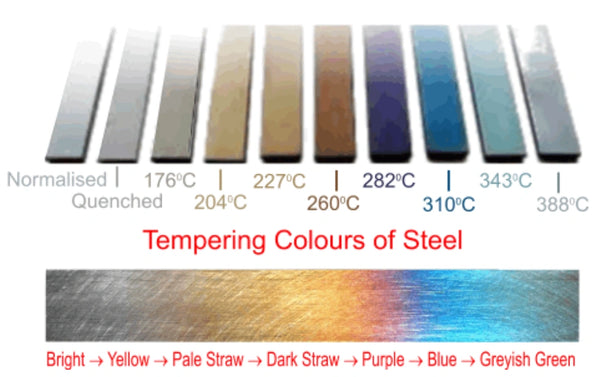

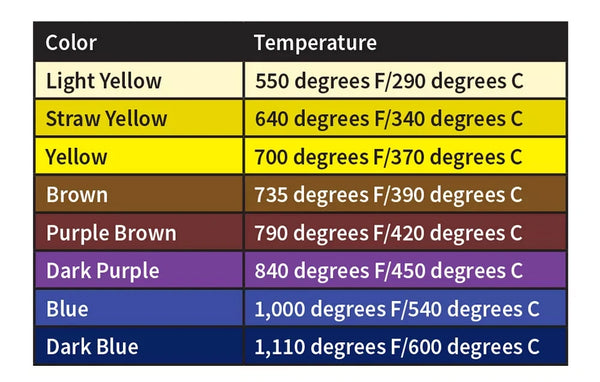

As noted, the colors in the weld appear in a predictable pattern based on the amount of oxidation that has occurred on the surface or all the way through the metal. The color scale is:

Source: https://wiki.dtonline.org/index.php/Heat_Treatment

- Chrome/No Color: Chrome, or no color, means there is no oxidation whatsoever, not even the thinnest layer on the surface. No color means your weld is structurally sound, and you won't have any corrosion or structural issues.

- Straw/Yellow/Gold: Straw color means that the smallest amount of oxidation occurred on the top of the surface. This thin layer typically won't affect the integrity or strength of the weld, and it is acceptable in most applications.

- Red: Red is the middle ground and the turning point in most applications. It is a sign that oxidation started penetrating the surface, which can be unacceptable in critical applications.

- Blue/Purple: Once the weld turns blue or purple, especially in the darker shades, it is a sign that molten metal reacted with the atmosphere and picked up oxidation, which now penetrated deeper layers of the weld. Extensive oxidization creates wrinkles, which are never a good sign of a solid and uncompromised weld, even though light blue is sometimes acceptable.

Blue Weld

Credit to @Roody welds (Facebook)

- Dull gray/ Black: The black or dull gray color means the weld is overcooked and wholly oxidized. In this case, the oxidation fully penetrated, and the weld completely lost its corrosion resistance. Even though colors are something to look for in weld art, black and dull gray don't have an aesthetic role, so you want to avoid them.

Colors In Stainless Steel

Stainless steel is a common name for a group of metals primarily made from iron and carbon, like other steels, but with the added chromium oxide, which gives it corrosion resistance. Besides the ability to resist corrosion, stainless steel is also a ductile material that is highly aesthetic, strong, durable, and long-lasting, with a low lifecycle cost and high and low-temperature resistance.

Like regular steel, as stainless steel heats, it can pick up hydrogen, nitrogen, and oxygen, resulting in surface oxidation and, yet again, colors. The oxidation on the surface is compromising corrosion resistance, which is why many use it in the first place. The oxidation prevents the natural regeneration of the passive layer of chromium oxide.

As a result, colors in stainless steel tell us chromium has migrated to the surface, leaving behind a chromium-depleted region. Stainless steel without chromium is a regular steel that can rust due to atmospheric exposure. The darker color signifies deeper oxidation in the hot welded area, so your exposed piping can quickly fail due to poor stainless steel's final properties.

So, while appealing, those deeper colors are not something you necessarily want when welding stainless unless you are into welding metal art. The chemical makeup of stainless steel makes this material very popular among artists who don't care about the material integrity of the weld. The art is designed to be beautiful, not strong, so cool colors are something to look for in those applications.

Colors in Titanium

Titanium is another strong and corrosion-resistant material with a great weight-to-strength ratio, making it useful in many industries, such as chemical processing, offshore, and aerospace applications. It also is used in prosthetic devices because it does not react with fleshy tissue and bone.

Source: https://www.cmpionline.com/sanitary-welding-what-is-it-and-what-is-it-used-for

Like stainless, titanium also forms a resilient protective oxide layer that protects it from corrosion. However, titanium is highly reactive, especially when it meets hydrogen, nitrogen, and oxygen found in the atmosphere. Unlike stainless, these elements play and affect the entire molecular structure of titanium, which can compromise the structural integrity of the whole material.

Even though it depends on the industry and use, you'd like the titanium weld and HAZ to come out a bright silver/chrome color. This is the first sign that your weld is strong and rust-resistant. Once again, elevated temperatures can create colors that look dang cool, but the less color, the stronger the weld. The quick and dirty version is that you want to avoid colors in titanium unless you are an artist who wants beautiful results on your art or hot rod car.

How To Avoid Getting Colors In Welding

After everything we said, it is clear that if you want to achieve strong and cleaner welds, you will want to avoid getting colors. The first step in avoiding the colors is understanding why they appear, which should be clear by now, but let's closely explain the solutions and tips for achieving strong and colorless welds. The key to best results during the MIG or TIG welding is:

- Control the heat exposure.

- Practice technique.

- Provide stable shielding.

- Adjust post flow.

Control The Temperature

The steel changes its color once it reaches a specific temperature, so you must be careful during the welding. Welding often involves reaching high temperatures that are high enough to melt the pieces and welding rod and fuse them. However, each metal reacts differently to the heat. Some metals, such as copper, have high thermal conductivity, which means they dissipate the heat, while some, like aluminum, can quickly get burned through.

Source: https://www.thefabricator.com/thefabricator/article/shopmanagement/all-you-need-to-know-about-the-heat-affected-zone

Heat control, including adequate amperage, is the key to avoiding getting the color or lousy weld. The heat should be enough to melt and fuse the pieces but not to burn through them. Too high amperage can burn through it or create colors; too low amperage can create a lack of fusion.

That's why most welders use TIG welding with inert shielding gas since it is known for its temperature control. Features such as pulse or pedal control, which you can find at our YesWelder TIG200P AC/DC, will allow you to reach the desired temperature without overheating it, which is crucial when welding thin or delicate metals.

Proper Welding Technique

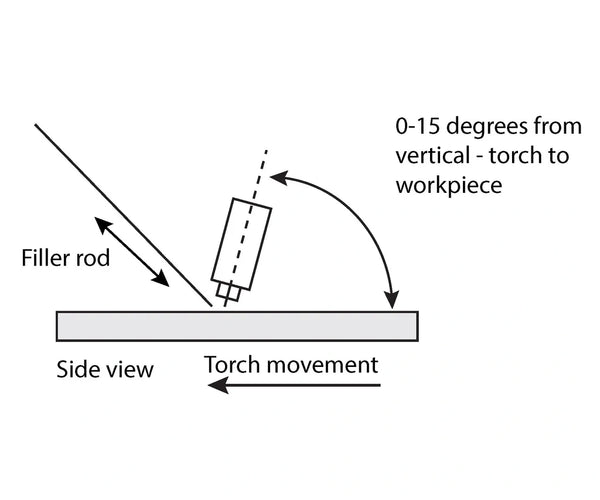

The welding technique includes properly manipulating the torch and keeping the filler feed and travel speed consistent. Most applications will require a torch angle of 10-15°, while a steeper torch angle (such as 45°) will severely decrease trailing gas, which means more color again as the weld will be hotter when exposed to the atmosphere.

In addition, the travel speed can create colors. Going too slow exposes the surface to high heat. High heat with longer exposure opens the door for oxidation, creating the colors. Therefore, practicing the welding technique is crucial when achieving sound and colorless welds.

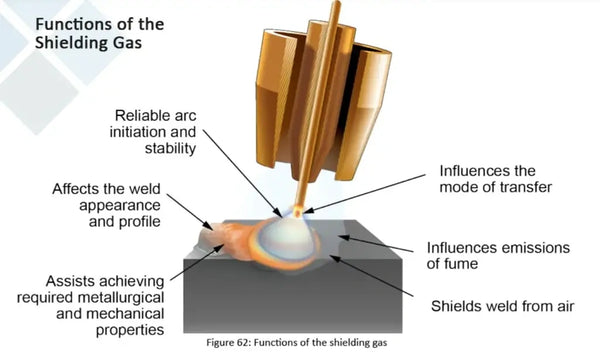

Shielding Gas Coverage

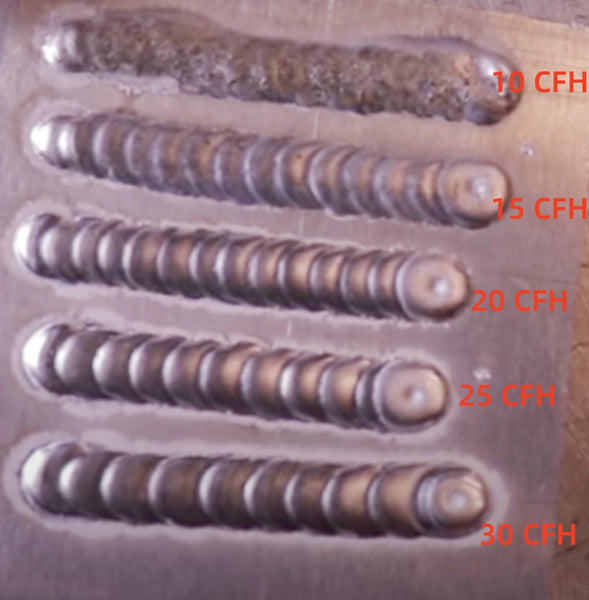

Colors also occur as the molten metal meets the atmosphere, and that's where the shielding gas kicks in. The shielding gas creates a protective barrier that covers the molten metal and prevents the reaction. Providing solid and reliable shielding requires good shielding gas coverage and adequate gas flow.

The shielding gas coverage is how much of your weld is being covered by the gas being pumped out. The gas comes from the external cylinder and goes through the hose and into the torch. In the torch, the gas can come from the collet body or gas lens into the nozzle.

A collet body releases a broad plume of gas over the weld pool to keep it shielded, but there's no real direction except out, which can lead to turbulence. A gas lens disperses the gas evenly across the weld pool in a laminar pattern with way less turbulence.

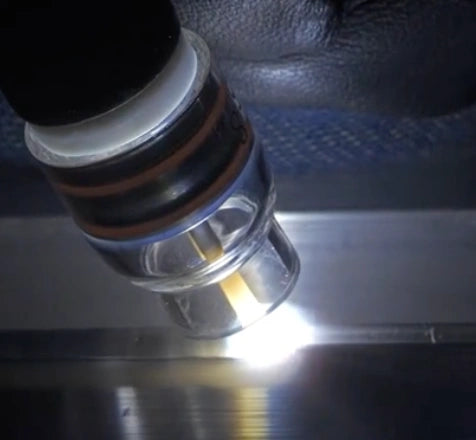

TIG Welding with Gas Lenses

Photo by @grumpyweld (TikTok)

The choice of gas coverage can create a big difference and yield a good weld. Most welders use gas lenses in critical applications, where a critical temperature can create a maximum risk of a chemical reaction and create colors. Meanwhile, a collet body is a cheaper option for everyday welding, but it can create shielding issues in high-quality applications.

However, gas coverage is nothing without the correct flow rate, and vice versa. However, keep in mind that more is not always better. Setting too high a gas flow rate can create turbulence, which can suck in the atmosphere. In a garage or shop, 10-15 CFH will do just fine, but with draft and outdoors, you will want to tune it up to 20 or even 30 CFH.

Adjust Post Flow

Post flow in TIG, and sometimes in MIG welding, is crucial in cooling down the weld and your components. Cooling down the end of the weld creates a minimum risk of cracks or contamination at the end of the weld.

Finishing the weld is as essential as keeping the ideal temperature and coverage through and in the middle of the weld, so you will want to protect it thoroughly. Besides colors, adjusting post flow will also prevent the formation of craters and cracks at the end of the weld, which is once again critical when composition lends itself to the best result.

How To Get Colorful Welds?

If you want to get into the welding art, you might wonder how to get colorful welds. Well, the answer is pretty simple: you need to do everything opposite of what we learned in the previous section of the article.

You'll need a material or alloy with colorful reactions, such as stainless steel or titanium, to get the colorful welds. Clean and polish the surfaces so they can properly show the colors. Use the shielding gas, but with adjustments that allow small amounts of oxidation that show colors. Continuously monitor color changes during welding, making real-time adjustments to heat and welding techniques to get that desirable color scale.

Source: https://www.youtube.com/watch?v=6lOl98EkqCY

Final Thoughts

Understanding the colors in welding is not just a visual spectacle but a crucial aspect of the welding process. The vibrant spectrum, from the initial silver chrome to the intense purple, serves as a temperature guide, aiding welders in achieving optimal results.

Mastery of these color cues allows precise control over heat input, ensuring the integrity of welded joints. Beyond the technicalities, appreciating the colors in welding transforms the craft into an art form.

🧐What Do Colors Mean in Welding FAQ

1. Are colors in welding good?

Colors in welds can be desirable in artistic welding, adding vibrancy to metal art. However, in critical applications such as pharmaceutical or sanitary welding, any color beyond light gold or chrome is unacceptable due to potential oxidation affecting corrosion resistance and creating weak spots.

2. How To Avoid Getting Colors In Welding?

-

Control heat exposure

-

Practice technique

-

Provide stable shielding

-

Adjust post flow

👏 You may be interested in the following:

Leave a comment