Stick Welding Safety Tips: How to Protect Yourself

If you are new to Stick welding, you are likely to get burned, shocked, or flashed. Welding safety is the first step in any welding operation, particularly Stick welding.

At its core, Stick/Arc welding burns hotter than processes such as MIG or TIG Welding. Thus, you must be prepared to prevent hazards before they occur.

In this article, we will discuss Stick welding safety and important Arc welding tips to help you improve the safety of your workshop. As long as you follow the safety protocols in and around your workplace, you can weld safely. So, let's explore more.

Vertical Stick Welding with E7018 Rods

Photo by @sewingwithfirewelding (TikTok)

Is Stick/Arc Welding More Hazardous Than Other Methods?

All welding methods carry a potential risk of burns, IR/UV radiation, eye damage, fume exposure, fire, or even explosion. However, Stick welding is known as the most dangerous one. But why?

Stick welding runs hotter than other welding techniques, meaning its arc produces more heat and radiation. This heat makes it favorable among welders worldwide who use it in applications such as construction, repair, pipeline, farm, or ranch.

Nonetheless, this heat poses a higher risk of burns. Stick welding uses self-shielded electrodes covered with flux. As the flux burns, it releases toxic fumes. Prolonged exposure can cause health risks or metallic fume fever.

Higher heat also means more spatter and a higher level of radiation. Molten sparks can cause fire if they come in contact with flammable liquids in your garage or workplace. IR/UV radiation can damage your eyes or cause sunburn to exposed skin.

Although it sounds grim, you can avoid all these hazards simply by using adequate PPE (Personal Protective Equipment) and following the safety protocols in your work area. So, let's see what you'll need and what you have to do to keep yourself safe when Stick welding.

Source: https://safetyculture.com/topics/welding-safety/10-welding-safety-rules/

Stick Welding Protective Equipment

The first step in any welding process, including Stick welding, is using the proper personal protective equipment (PPE) for your job. The stick/Arc welding PPE checklist includes the following:

-

Welding helmet

-

Welding gloves

-

Fire-resistant jacket

-

Welding pants

-

Welding boots

-

Stick welding respirator

-

Ear muffs or plugs

The listed equipment is the core PPE for any welding method, but there are some specifics closely related to Stick welding. Let's see the options.

Welding Safety Checking List

Source: https://weldingofwelders.com/ppes-for-welding/

Stick Welding Helmet

A welding helmet is a mandatory piece of PPE that will protect your eyes and face from the IR/UR radiation produced by the arc. As noted, a Stick welding arc produces more radiation than other processes, so it is crucial to protect your eyes and face.

For Stick welding, you should use a welding helmet or shield with at least shade #10 for applications up to 200 amps. High amp applications over 200 amps will need shades up to DIN 14.

Although you can use a hand shield, we always recommend a welding helmet. An auto-darkening helmet, such as the YesWelder MP800HP, will help you focus on the work and use both hands for better coordination and manual dexterity.

LYG-M800HP True Color View Auto-Darkening Welding Helmet

Besides eyes, a welding helmet also protects your face from radiation. Using goggles or a mask without a leather cover will cause bad sun-like burns to your face and neck, so always cover your skin.

Stick/Arc Welding Gloves

Stick welding without protective gloves can cause severe burns to your hands. The arc emits radiation and heat, so gloves are needed when welding close to the joint. Additionally, the base metal around the welds gets hot during the welding, so leaning on it can cause burns.

For Stick welding, we recommend using thicker, fire-resistant leather gloves. Thicker gloves will protect your hands from high heat caused by Stick welding, so make sure you check YesWelder AP1201 gloves.

AP-1201-1 Heat-Resistant Fire-Retardant Leather Welding Gloves

Remember that the thicker the gloves, the more heat they can withstand. However, that is not always the best solution. Thick materials can affect your manual dexterity and electrode manipulation. So, always look for gloves that provide a perfect balance between protection and agility.

Stick Welding Jacket

Welding jackets are made of heavyweight, tight-woven cotton, denim, or wool. These materials are fire-resistant, offering safety against fire and radiation.

For Stick welding, we recommend a long-sleeved welding jacket or a denim jacket with snaps rather than buttons. The materials will protect your skin from radiation and spatter, and the snaps will help you take your jacket off in case a flying spark ends up down your clothes.

Wearing a Long-sleeved Welding Jacket While Stick Welding

Stick Welding Pants and Boots

Similar to a jacket, pants protect your legs from radiation and sparks. Some manufacturers treat cotton fabrics with flame-retardant chemicals to enhance their fire-resistant properties. Since jackets or pants can be starchless and uncomfortable, treating cotton fabrics yields clothing that provides a balance between comfort and protection.

When buying Stick welding pants, make sure they are made of safe, fire-resistant materials. Don't forget comfort, as you could be wearing them the entire day. Make sure the length covers your boots, as you don't want sparks inside your shoes.

Proper boots will prevent burns and slipping and ensure optimum stability around the work area. Steel-toe shoes will protect your feet from sharp, heavy falling objects and other injuries that can occur during welding.

Wearing PPE When Stick Welding

Photo by @datboimiggz (TikTok)

Stick Welding Respirator

As noted, Stick welding produces excessive fumes during the procedure. The fumes come from molten flux, molten metal, and possible contaminants such as oil, paint, rust, or zinc. Prolonged exposure to fumes can cause various health risks, including metal fume fever, so you want to keep yourself protected.

Now, when in outdoor welding, fumes are not such a big issue. The wind and draft will keep them away from you, so you are safe in on-field work. However, when Stick welding in cramped spaces, you will need a welding respirator. The fumes build up in tight spaces, and a respirator will prevent you from breathing in heavy metal oxides and other toxic substances.

Wearing a Respirator While Stick Welding Indoors

Source: https://www.euromarc.co.nz/resources/are-safety-glasses-enough-to-protect-you-from-welders-flash

Stick Welding Ear Muffs or Plugs

Large-scale welding often involves working in a loud, hazardous environment. Spending an entire shift in an environment with loud noises associated with welding, cutting, or grinding can cause long-term hearing damage.

Always wear earplugs or earmuffs to reduce exposure to loud noises and prevent long-term hearing loss. Although you might not need them in your home Stick welding applications, remember to protect your ears.

Wear Ear Protection While Welding

Photo Credit: Adobe Stock

Stick Welding Safety Tips and Safety Precautions

As we noted, using PPE is just the first step in protecting yourself from Stick welding hazards. Next, you must be aware of possible risks in and around your welding environment and take precautions to make your Stick welding as safe as possible.

Spending more time preparing the welding area will create a safe and clean environment that yields the highest-quality welds. It is always better to prevent accidents than salvage them, so here are a few tips to help you stay safe during Stick welding.

Stick Welding a Pipeline in the 6G Position

Photo by @leslyrdz2 (TikTok)

1. Safely Set Up and Install Stick Welder

Before starting to weld or turning on the welder, read the instructions and warning labels. Also, make sure the welder's power options are suitable for your household. Your electrical system should be able to handle the increased load caused by the welder's electrical demands. Breakers popping off are never a good sign of a functional welder or a sound electrical system.

Protect the electrical network with an appropriately sized fuse or circuit breaker on an independent circuit. Also, make sure the welder's case or frame is adequately grounded. When using a high-amp Stick welding system, ensure you have a safety-type disconnecting switch or controller near the machine.

Use a circuit breaker on an independent circuit.

Source: https://instrumentationtools.com/circuit-breaker/

2. Always Wear Personal Protective Equipment

When you start welding as a beginner, you will likely get burned or flash. PPE, such as a welding helmet, gloves, or jacket, is essential for safety and should be your best friend during your welding adventures.

Always wear a welding helmet to protect your eyes from flashes and keep your skin protected from burns. Flame-resistant gloves protect your hands, while jackets, pants, and boots protect your body, legs, and feet from skin burns.

A welding respirator is a must-have when welding indoors or in cramped places. It will protect you from toxic fume exposure. Ear muffs or plugs will keep your ears safe when working in a loud, hazardous welding environment.

Always Wear Personal Protective Equipment While Welding

Source: https://www.canadianmetalworking.com/

3. Provide Proper Ventilation and Don't Breathe Fumes

Although stick/arc welding is often carried out in the open, in on-field applications, welding at home often involves working in a shop or garage. When Stick welding indoors, make sure you provide proper ventilation. Draft or natural airflow will prevent toxic fume buildup and excessive exposure.

Ensure proper ventilation when stick welding indoors.

Photo by @sewingwithfirewelding (TikTok)

According to OSHA (Occupational Safety and Health Standards), each welder in the workplace should have a minimum ventilation rate of 2,000 cubic feet (57 m(3)) per minute per welder. For your home applications, you should be fine with natural ventilation.

However, Stick welding in tight, cramped spaces can cause fume buildup. In that case, you will need local exhaust ventilation, which is common in industrial and large-scale applications, or at least a welding respirator. The respirator can be linked to your helmet or can be used standalone.

Be careful when Stick welding material with a protective layer, such as galvanized steel, lead, or cadmium-plated steel. Burning these layers creates highly toxic fumes that can cause severe damage to your lungs. To reduce the exposure, constantly remove the protective layer before welding.

Remove the zinc coating by grinding before welding.

Photo by @taylor_welding (TikTok)

4. Avoid Fire Hazards

Stick welding produces temperatures higher than 10,000 degrees F and more spatter than other methods, meaning you should be careful about your surroundings. Before welding, remove all flammable materials from the area. Keep combustible materials at least 35 feet away from the welding area.

If you weld in a garage, make sure there are no oil, petroleum stains, or gas cans around the weld area. Before beginning to arc-weld, remove combustible items, such as matches or lighters, from your pockets. A spark can easily ignite these combustibles, causing a fire that can be hard to put out.

When indoors, weld on solid, concrete ground. Cracks and holes in the concrete can trap sparks and consumables, causing fire. Spatter can even cause explosions if it continuously strikes compressed air cylinders or pressurized shielding gas cylinders. Therefore, always keep compressed gas cylinders away from arc-welding work areas.

Always have readily available extinguishing equipment, such as buckets of sand or an ABC dry chemical extinguisher, in case of fire. For home applications, a #10 fire extinguisher should be large enough to handle the fire.

Always keep fire extinguishers nearby when welding.

Source: https://trainingnetwork.com/products/preventing-fires-during-hot-work-operations

5. Avoid Electrical Hazards

Stick welding can cause an electric shock, but in most cases, these are small shocks that won't kill you. The process uses Open Circuit Voltage (OCV), and it becomes electrically "live" as soon as you turn on the welder. The OCV voltage is commonly higher than 50V, and it must be high enough to provide reliable arc starts.

If you accidentally close the circuit, you will be shocked. Standard shocks occur once you touch the live electrode while leaning on the grounded base metal. However, when the resistance of the dry skin reaches 100,000 ohms, you only feel small, non-life-threatening shocks. This is a secondary electrical shock, and it occurs at lower voltages up to 100V.

Meanwhile, touching the electrically live internal components or damaged cables can cause a primary shock in Stick welding. This shock uses a primary voltage, which can reach 600V and cause electrocution. However, most welder cases today are grounded, so the shock blows the fuse rather than electrifying you.

Source: https://link.springer.com/article/10.1007/s40194-013-0103-x

Remember that conditions change once you work in damp areas. Moisture, sweat, and water lower the electrical resistance of the skin, causing more severe shocks.

To avoid shocks in Stick welding, turn off the welder before changing the electrode, or make sure you are not closing the circuit with your body. Additionally, avoid working with wet equipment in damp places, and remove excess moisture from your body before welding. Check the cables for damage and broken wires.

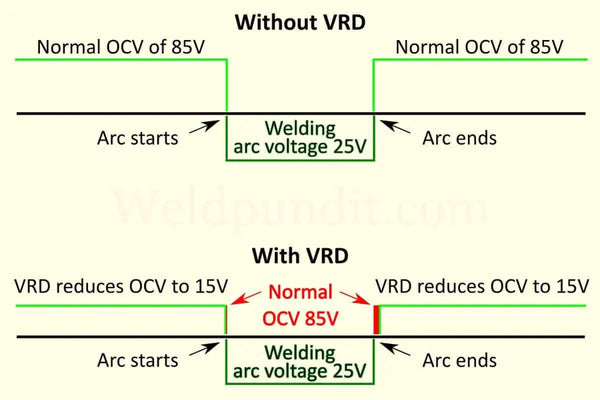

Newer Stick welders also use a feature called a Voltage Reduction Device (VRD). When on, the device lowers the open circuit voltage to reduce the risk of shock. Once it senses that you are starting an arc, it pumps up the voltage to provide a reliable start.

How VRD Affects Open-circuit Voltage

Source: https://www.weldpundit.com/voltage-reduction-device-vrd-in-welding-beginner-guide/

6. Properly Store and Maintain Stick Welding Equipment

Knowing the limits of your equipment will significantly prolong its lifespan. Stick welders are relatively straightforward machines, but you still have to clean them regularly.

Before the maintenance, turn off the inverter, disconnect the power cord, and discharge the capacitors. Dust, metallic particles, and dirt can interfere with the standard power supply, causing inconsistent results. So, make sure you clean the welder, its case, and cables periodically.

Clean the Welder Periodically

Source: https://www.youtube.com/watch?v=VRZDeQmrnPk

Visually inspect the connections and cables. Wires sticking out of your leads are never a good sign, and they can cause shocks or underperformance. Thus, you should always replace them. Loose connections can cause voltage drops and an inconsistent arc. So, make sure everything is in place before starting your next weld.

Remember to store your Stick welding equipment properly. Keep your welder away from damp and moist places, as they can damage the internal components or cause rust or corrosion. Also, take good care of your Stick electrodes. Keep the electrodes away from moisture, especially low-hydrogen ones, as humidity can affect performance and safety.

Proper Storage of Stick Electrodes

Source: https://www.thefabricator.com/thewelder/article/consumables/storing-smaw-electrodes

7. Avoid Clutter in the Workplace

A messy workplace poses a possible risk of injuries. Cables and leads connect accessories to the welder or electrical outlet, but if thrown around the workplace, they can cause injury. If unattended or poorly stored, cables can wrap around your legs or body or cause you to trip.

Therefore, after welding, make sure you properly store your electrode holder and wrap the leads. Remove the electrode from the holder, and store it away from common paths you or your employees use.

https://www.reddit.com/r/Welding/

8. Prevent Stick Welding Injuries

Stick welding, like any other occupation, presents a risk of possible injuries. Sharp, heavy metals can always hurt you, and there is an even greater risk of repetitive strain injuries.

To prevent Stick welding injuries, secure workpieces with clamps. Clamped pieces won't fall on your toes and will promote precision during the welding. Brush the sharp edges and keep the excess metal away from your workplace. In case of injury, keep a well-stocked first aid kit handy.

Secure Workpieces with Clamps While Stick Welding

Source: https://www.youtube.com/watch?v=Mpc2ly6x6hk&t=2s

Shielded Metal Arc Welding (SMAW) also poses a risk of repetitive strain injuries. Working in uncomfortable positions for prolonged periods may injure your back, muscles, or hands.

While Stick welding in uncomfortable positions is standard for on-field jobs, you can avoid this at home. Place your pieces in the horizontal or flat position, high enough so your back is not subjected to pressure. Try to rest your hands or elbows on the table as you weld to provide good support for your body and promote precision.

Stick Welding in Comfortable Positions

Source: https://www.youtube.com/watch?v=8U8ZNNR39lo

Key Points of Stick Welding Safety

To sum things up, here is a list of key points in Stick welding safety you should remember:

-

Read the manual and warning labels, and properly install and ground the welder

-

Always wear Personal Protective Equipment, including a welding helmet or a shield, gloves, jacket, pants, and boots.

-

Clothing should be fire-retardant to protect you from heat, radiation, and burns.

-

Stick welding helmet should have at least shade #10

-

Don't breathe in the fumes.

-

Weld with sufficient ventilation, and use a respirator or local ventilation when welding in tight places.

-

Prevent fire by removing the combustible materials from the work area.

-

Never weld, cut, or work on used drums, barrels, tanks, or other containers.

-

Mark recently welded metal "HOT" with a soapstone.

-

Be careful with an electrically live circuit

-

Don't weld in damp or moist areas or while standing in water

-

Properly maintain and store your Stick welder and welding electrodes

-

Avoid clutter in the workplace to reduce the risk of injuries

-

In case of injury, keep the well-stocked first aid kit nearby

-

Prevent repetitive strain injuries by working in a comfortable position

Stick Welding Process

Photo by @ayon_weldingco (TikTok)

🧐 Stick Welding Safety Tips: How to Protect Yourself FAQ

👏 You may be interested in the following:

Leave a comment