How To Weld Galvanized Steel

Galvanized steel is widely used across various industries due to its enhanced corrosion resistance and durability. However, welding galvanized steel requires precision and knowledge to navigate the challenges posed by the beneficial zinc coating.

Burning through zinc coating creates toxic fumes that can affect your health, cause metal fume fever, or even have adverse long-term effects, so understanding how to weld galvanized steel is crucial. In this article, we will closely explain what galvanized steel is, why it is widely used, and how to weld galvanized steel successfully without compromising your health or final results.

What Is Galvanized Steel?

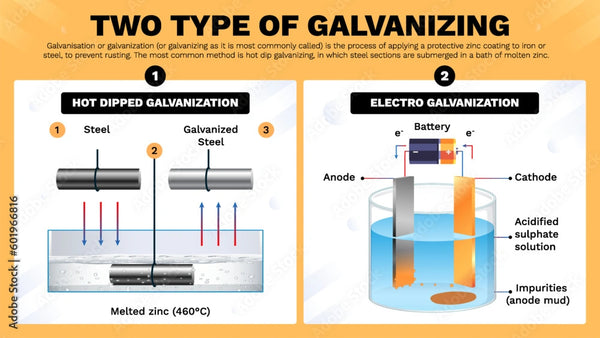

Galvanized steel is a regular steel that has been coated with a layer of zinc to promote corrosion resistance. This is carried out through a process of galvanization, which involves applying a protective zinc coating to the surface of the steel through various methods. The most common methods are hot-dip galvanization and electro galvanization.

- Hot dip galvanization involves dipping the steel in a bath of molten zinc. The high temperature causes the zinc to react with the steel, forming a series of zinc-iron alloy layers. As the steel is withdrawn from the bath, a pure zinc layer is often deposited on the outer surface. This creates a dual-layer protection that significantly improves steel's resistance to corrosion.

- Electrogalvanization is the process of galvanizing steel that involves electroplating, running a current of electricity through a saline/zinc solution with a zinc anode and steel conductor. The zinc ions bond to the steel's surface as the electric current is applied, creating a thin, protective layer. This method produces brighter, more aesthetically appealing deposits with a thinner layer than hot-dip galvanization.

How Zinc Coating Protects The Metal?

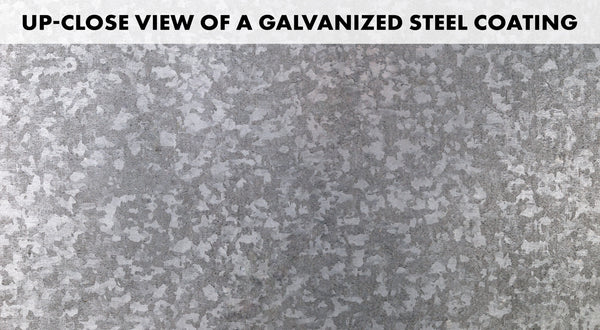

The zinc coating on galvanized metal serves as a sacrificial anode. In the presence of corrosive elements, such as moisture and oxygen, the zinc corrodes preferentially to the steel. This sacrificial corrosion helps protect the underlying steel from rust and extends the material's lifespan.

Source: https://sheffieldmetals.com/learning-center/what-is-galvanized-steel/

This sacrificial process contributes to the self-healing nature of the coating, particularly when scratched or damaged. If the coating is scratched or damaged, the zinc surrounding the damaged area can provide cathodic protection, slowing the corrosion process.

The zinc coating significantly enhances the durability of the steel, making it suitable for various applications in harsh environments. Its resistance to atmospheric, water, and soil corrosion leads to a longer lifespan compared to untreated steel. Moreover, the zinc coating maintains its integrity during a metal fabrication process, such as welding and forming, without flaking or peeling.

Applications Of Galvanized Steel

Galvanized steel is widely used across various industries due to its enhanced corrosion resistance and durability. Galvanized steel is all around us in multiple sectors, including road, rail, energy plants, oil and gas, agriculture, water and waste, and sports and leisure. It can be essential in buildings, bridges, facades, signal gantries, gates, balconies, and even sculptures. Wherever there is a risk of corrosion, galvanizing should be used.

Source: https://yenaengineering.nl/a-complete-guide-to-galvanized-steel-for-2021/

What makes galvanized steel so widely used is its cost efficiency. The galvanization process only slightly increases the price, which is barely higher than untreated steel. However, compared to stainless steel, galvanized steel is 3-4 times more expensive. However, there are applications in which each is more useful. For example, galvanized steel is often used in structural steel that's exposed to atmospheric contamination, while stainless steel is more effective and resistant to salt water and other critical applications.

Welding Galvanized Steel

Welding galvanized steel is not inherently difficult, but there are considerations that you need to take into account to ensure a successful weld and avoid potential health hazards. The biggest challenges in welded galvanized steel come from the zinc coating that gives it positive characteristics.

Even though you can use any popular methods, such as Gas Metal Arc Welding (MIG welding) or SMAW, welding on galvanized steel without removing the coating can create zinc oxide fumes that can cause severe health issues. Other than that, galvanized steel steel is welded just like any other steel.

Health Hazards When Welding Galvanized Steel Products

Since the boiling point of zinc is lower than the melting point of steel, welding galvanized steel without removing zinc coatings creates zinc oxide fumes. The heat of the arc melts the zinc, which starts boiling and producing toxic fumes that can compromise your health. Additionally, you will have to take care of the spatter and high-temperature burns.

Short-term breathing in the zinc fumes can cause metal fume fever. This flu-like illness leaves a metallic taste in your mouth and causes symptoms such as fever, shaking, chills, fatigue, muscle and joint aches, and headache. The symptoms may be delayed for a few hours and typically last a day or two. However, welders who have had long-term exposure to zinc metal fumes may develop severe lung disease and risk of cancer.

Protecting Yourself From Zinc Fumes

The best way to protect yourself when welding galvanized steel is to wear proper protective equipment and remove zinc coating before welding. Right protection equipment when welding galvanized steel includes wearing welding gloves, clothing, and eye protection to minimize skin contact and protect against potential splatter of the boiling zinc and weld metal. Even though this is typical protective equipment, you must also follow other safety precautions, which include wearing proper respiratory protection and using a fume extractor when welding in confined spaces.

A dedicated welding respirator is crucial in protecting you from breathing in molten galvanizing zinc. A standard dust mask or dust respirator will not work since it won't protect you from harmful fumes. However, when welding galvanized steel in confined spaces or without proper ventilation, you will need a fume extractor or local ventilation system. These devices capture the fume emission at the source and transport it to a safe emission point or a filter/scrubber.

Another good practice is removing a zinc-coated portion. When you remove the zinc coating, you can weld the base metal like any regular steel without the health risks. However, the newly formed surface of bare metal is not corrosion-resistant. That's why it is essential to re-galvanize the weld joint.

Galvanized Steel Weld Preparation

Before laying your first bead on galvanized steel, you'll first need to prepare the pieces and employ safety measures. Make sure you are welding in a well-ventilated area and use protective equipment such as leather jackets, gloves, clothing, and welding helmets.

Weld preparation includes removing the zinc coating. You can do it by grinding with a sheet of 220-grit sandpaper, but when doing so, be aware of the zinc dust, which can also present a health hazard. So when grinding, make sure you wear a respirator and protective gloves and provide good ventilation.

Once the weld area is ready, align and clamp the pieces. Weld preparation in galvanized steel welding is nearly half of the entire weld. Preparation is an important and valuable technique that will allow you to weld galvanized steel successfully and safely.

Welding Methods For Galvanized Products

Galvanized steel, when correctly prepared, can be welded with any popular arc welding methods, but welders prefer MIG or Stick welding. In specific cases, welders also use oxyacetylene, resistance welding, or stir welding on galvanized steel, but these techniques require proper training and are often reserved for a more skilled welder.

- MIG, or Gas Metal Arc Welding, is one of the most popular beginner welding methods, especially when welding regular steels. If you remove the zinc coating, you can use any standard steel filler material wire and welding techniques for steel. The recommended parameters will depend on the material thickness and try to limit the heat input into the welding area to prevent surrounding zinc from heating up and creating fumes. If you are using multiple passes, make sure you make 10-15-second breaks. If you use flux core arc welding alternative, take 10-15 minute breaks to allow flux to lay down and protect the bead.

- Stick or Shielded Metal Arc Welding is another popular method for galvanized steel, and it can be used to weld through a thin layer of zinc coating produced by electro-galvanization. There are no unique rods for galvanized steel, but you can use a welding electrode that can burn through surface layers, dirt, or rust (such as E6011 and E6010). Burning through the surface layer will create fumes, so it is recommended when you need to get the job done quickly. Due to its good performance on weld metal with a surface layer, the filler rod will produce proper penetration and good-looking welds.

TIG welding galvanized steel is not recommended since zinc can contaminate and react with a non-consumable tungsten electrode, creating fumes long after you are done welding. You can use GTAW, but only if you remove the zinc layer. However, since it is less cost-efficient and beginner-friendly than MIG, most welders don't recommend it.

As noted, galvanized steel can be resistance welded or friction stir welded. These methods produce less heat, which means lower chances of boiling and zinc oxide fumes forming, but it requires specialized equipment and proper training.

Re-galvanizing Steel After Welding

If you removed the zinc layer before welding (which is recommended), you should re-galvanize the steel after welding. The newly formed weld can have corrosion issues due to zinc loss, which creates a weak spot. The coating issues will cause corrosion in the weld, compromising the structural integrity of the entire weld.

The excellent thing about galvanization is that you can do it at your home. Even though hot-dipping is an excellent way to re-galvanize the pieces evenly, melting the zinc and dipping the pieces can be dangerous at home, so consider electro-galvanization, zinc chloride solution, or zinc-rich paints.

While not as durable as hot-dip galvanizing, zinc-rich paints may last decades as long as they're not in a location where they're likely to get abraded, chipped, or scratched. Zinc electroplating can also be done at home, and you can buy kits. Typically, using a zinc bromide-based electrolyte will help, but ensure adequate ventilation.

Quick Tips For Successful And Safe Galvanized Steel Welding

- Provide proper protective equipment and ventilation to keep yourself safe during welding.

- Prepare galvanized steel pieces by removing the zinc coating that can create toxic fumes.

- Wear protective and respiratory equipment when grinding the pieces to protect yourself from zinc dust.

- Align, clamp, and tack the pieces in place to reduce the risk of distortion or warping.

- Use the anti-spatter spray into the weld joint to reduce the risk of zinc spatter.

- You can apply a thin coat of flux to prevent oxidation at the beginning of the weld.

- Always wear a welding respirator and use a fume extractor or local ventilation when welding in cramped spaces.

- If you removed the zinc coatings, you can use the MIG welding process with regular steel welding wire, such as ER70S-6 solid MIG wire.

YesWelder ER70S-6 Solid MIG Wire

- If there is a thin zinc-coated portion, you can use SMAW with E6010 or E6011 electrodes that can burn through contaminants or a surface layer.

- When burning through the surface layer, make sure you protect yourself from fumes, limit the heat to avoid unnecessary spatter, and check if the welds properly penetrated both pieces.

- Re-galvanize the welds after welding. Removing the protective coating will create weak spots that need to be re-galvanized by any galvanization method or simply by using zinc-rich protective paints.

- If you use galvanizing paint, make sure welds are not exposed to wear, scratching, or tear.

Final Thoughts

In conclusion, welding galvanized steel demands a balanced approach that prioritizes safety, meticulous preparation, and the application of appropriate welding techniques. The challenges posed by the zinc coating, including the release of potentially harmful fumes, necessitate stringent safety measures.

Adequate ventilation, respiratory protection, and proper personal protective equipment are imperative to mitigate health risks. Ultimately, a cautious and informed approach ensures both the welder's safety and the creation of durable, high-quality welds on galvanized steel.

🧐How To Weld Galvanized Steel FAQ

1. How to prepare for welding galvanized steel?

Before beginning to weld galvanized steel, ensure proper preparation and safety measures. Weld in a well-ventilated area and use protective gear like leather jackets, gloves, and welding helmets.

Remove the zinc coating by grinding with 220-grit sandpaper, but be cautious of zinc dust hazards by wearing a respirator and protective gloves. Align and clamp the pieces securely before welding. Effective weld preparation is crucial for successful and safe galvanized steel welding.

2. What are the welding methods for galvanized products?

Galvanized steel, when correctly prepared, can be welded with any popular arc welding methods, but welders prefer MIG or Stick welding. In specific cases, welders also use oxyacetylene, resistance welding, or stir welding on galvanized steel, but these techniques require proper training and are often reserved for a more skilled welder.

👏 You may be interested in the following:

Leave a comment