Welding Tips For Beginners And New Welders

Welding today has evolved from a highly specialized occupation to an everyday hobby and DIY's favorite. However, getting into the world of welding can be stressful and long, filled with trial and error.

Even though welding is easier than ever, many new welders struggle to understand the basics and lay the perfect weld. Welding is one of the professions you can start learning independently, but you will still need to know a couple of things before you start.

Why we compiled practical welding tips for beginners to give you a head start into this magnificent trade we all love.

Practice Out of Position Welds

Source: https://www.youtube.com/watch?v=1jsj3o15GVo

Welding Basics

Welding is a fantastic and strong metal joining process that creates an everlasting bond. This process uses heat produced by a welding arc, friction, flames, reactions, or laser to melt and fuse the pieces.

High heat from one of the sources melts the base metal and filler metal. Filler metal deposition creates a weld bead or weld, which is a central piece of this metal joining process.

Arc Welding Basic Explained

Source: https://www.perfectwelders.com/arc-welding-the-5-welding-processes-you-need-to-know/

Even though the basics of welding sound simple enough, embarking on the journey of welding is a long process that requires patience, tenacity, and dedication.

How To Start a Welding Career?

Today, you can start your welding career or learn the trade for your hobby, home, or DIY projects. The first and easiest way is to buy a hobby welder and start practicing on your own. There is a ton of helpful information on the YesWelder blog, and you can also watch YouTube videos.

Although self-learning will get you far, you need a welding course or school to excel in your career. Licensed welding instructors will teach you more than just how to join two pieces. You will learn about safety, metallurgy, and advanced techniques.

Source: https://denvertoollibrary.org/welding-classes

Helpful Welding Tips For Beginners And New Welders

Regardless of the way you choose to start your welding career, you will need to know several things about welding. So, we will give you a head start and some helpful information to stop you from making rookie mistakes right at the beginning of your journey.

So, let's see what you should do as a beginner or new welder just learning how to weld.

|

Tips |

Suggestions |

|

Stay safe during welding |

Use proper PPE, including a welding helmet, long-sleeved jacket, and gloves. |

|

Choose the suitable welding method |

Get into the world of welding with MIG, and master other techniques |

|

Learn more about welding equipment |

Read the instructions for each piece of welding equipment (welder, helmet, torch, electrodes, etc.) |

|

Understand the metal you are welding |

Each metal has different characteristics, metallurgy, and weldability |

|

Prepare welds |

Clean the surfaces, align and fit up the pieces |

|

Set the amperage and voltage |

Use the manufacturer's recommendations or smart settings to set up the parameters |

|

Shield the welds |

Use external shielding gas with MIG and TIG welding to protect welds from contamination |

|

Practice the technique |

Find the sweet spot between arc length, travel speed, angle, and manipulation |

|

Play with weld puddle |

Experiment with parameters and technique |

|

Get comfortable |

Weld in comfortable positions to avoid long-term injuries |

|

Clean and store equipment |

Clean the workplace to avoid clutter and hazards. Store equipment in a clean, moisture-free environment |

1. Safety first

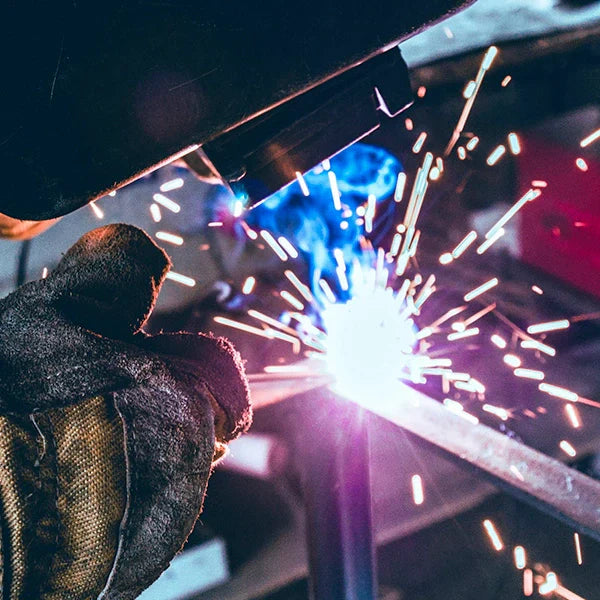

Welding is a hazardous profession associated with high heat, radiation, and fumes. Molten sparks fly around the workshop and can cause burns or start a fire. Welding arc emits UV/IR radiation that can damage your eyes or burn the skin like sunlight. Melted metal layers and electrodes create toxic fumes that can cause metallic fume fever.

Main Welding Hazards

So, before even considering welding, you should first consider safety. Always use PPE (Personal protective equipment), including welding gloves, welding helmet, and long-sleeved jacket. When welding in confined spaces, or burning zinc layer or flux-cored wire, use proper ventilation or welding respirator.

Protecting yourself from welding hazards is the first and crucial step in safe welding. Limiting yourself to exposure can provide many years of good health and safe welding.

Source: https://www.youtube.com/watch?v=_svEOII-Xgg

2. Choose the suitable welding method for your projects

The four most popular welding methods are MIG welding (GMAW), Stick welding (SMAW), TIG Welding (GTAW), and Flux core welding (FCAW). You will likely use these arc welding methods as a beginner or a new welder, but which one is right?

4 Types of Welding Explained: MIG vs. TIG vs. Stick vs. Flux Core

Source: https://www.youtube.com/watch?v=y-OKi8oSNQ4

There is no simple answer, as choosing the suitable welding method will depend on the following:

-

Metal thickness

-

Metal type

-

Weld aesthetics and quality

-

Welding conditions (indoor or outdoor welding)

-

Welding skills

Since we are overviewing things from the perspective of new and beginner welders, welding skills concern you the most. We recommend starting with MIG welding for any beginner and new welder.

Gas Metal Arc Welding (GMAW) or Metal Inert Gas (MIG) welding is the most straightforward method favored among beginners and new welders. MIG's semi-automated principle and features, such as smart parameter matching, which you can find on YesWelder DP200 MIG welder, will significantly help you master the technique.

Firstess DP200 Multi-Process DualPulse™ MIG Welder

However, MIG is not without drawbacks. Stick and Flux core work better on thick stock, while TIG is better on sheet metal. TIG provides excellent heat control, allowing you to weld exotic and non-ferrous metals. But when it comes to ease of use, MIG is our favorite.

3. Get familiar with welding equipment

Take your time reading the instruction manual before starting to weld. Each welding machine is unique and provides distinct features and welding performance. So, get familiar with your equipment before starting to weld.

Read the Instruction Manual before Welding

The first step is setting up and connecting the machine. You can find all instructions concerning the suitable polarity, wire or electrode mounting, gas connections, etc., inside the instruction manual. Setting up the welder is just the first step.

You must also understand the limitations of your welder. Each welder has its rated output, which will directly affect the thickness of the metal you can weld. The duty cycle tells you how long you can weld before overheating. Exceeding the duty cycle can damage the internal components.

A 60% duty cycle allows 6 minutes of use and 4 minutes of cooling per 10 minutes.

Source: https://amarineblog.com/2019/09/05/what-is-duty-cycle-in-welding/

Take some time to get familiar with other accessories, such as a welding gun, torch or electrode holder, and electrodes or wire. Torches and guns also have a duty cycle, so try not to overheat them. Also, look at the specifications of the electrodes or welding wire you will use.

4. Know the metal you are welding

Each metal has different metallurgical and physical properties, which can directly affect its weldability. As a result, we have some easy-to-weld metals, such as mild steel, or hard-to-weld metals, such as aluminum.

Understanding the weldability of each metal can significantly help you make the right approach to welding. For example, some metals, such as cast iron, require preheating and post-heating to avoid cracks. Aluminum needs aluminum-oxide layer removal, and so on.

In addition, knowing the metal will also help you choose the suitable filler metal. The compatible filler or electrode will produce a strong bond, while incompatible filler can cause cracks or weld failure.

Source: https://www.youtube.com/watch?v=X1OuWvuWDEk&t=1030s

5. Prepare for welding

Preparation is a vital but often ignored step in welding. The more time you spend preparing and cleaning the pieces, the less time you will spend on post-weld cleaning and rework.

The weld preparation includes cleaning, aligning, and setting up pieces. It is not rocket science: clean surfaces yield clean, high-quality welds. Removing dirt, rust, oil, or paint will create favorable welding conditions. Although some processes, such as Stick or Flux core, can burn through light contamination, it is always better to clean the pieces before welding.

Clean the Metal before Welding

Photo by @suncityweldingacademy (TikTok)

Aligning and setting up pieces is also essential. An even gap across the joint creates even filler metal distribution and even welds. Weld joint design explains how two pieces are joined.

As a beginner, you should stick to a flat and horizontal position. Gravity pulls the molten metal inside the joint to produce even distribution. Butt welds and T-joints are perfect for all beginners.

MIG Welding in Flat Position

Source: https://www.youtube.com/shorts/kZg8E1cmldg

6. Dial in the amperage and voltage

Metal thickness, size, and type of electrodes dictate the amperage and voltage. You will need to find a sweet in which you get the proper penetration and fusion, without going too cold or burning through pieces.

Too low amperage will extinguish your arc or cause the electrode to short-circuit and stick to the base metal. Too high amperage will burn through the joint. Both are the conditions you should avoid.

Follow the manufacturer's instructions to calibrate amperage and electrode size before welding properly. In addition, you can use welders with smart MIG, such as YesWelder MIG205DS Pro, to automatically adjust the parameters according to electrode size, metal thickness, and shielding gas.

YesWelder MIG205DS Pro features a synergic mode.

7. Shield the welds

If you are using gas welding methods, such as MIG or TIG welding, you must protect the weld from atmospheric contamination. Gases from the atmosphere, such as oxygen or hydrogen, can interact with a molten weld puddle and create contamination. Porosity is the most common sign of contamination, so if you see small holes in your welds, you need proper shielding.

Source: https://blog.morganitech.com/porosity-common-welding-issues

External shielding gases, such as Argon, Helium, or CO2 are a common solution to this issue. Inert and semi-inert gases create a protective atmosphere around the weld. As a result, you can weld without a risk of contamination.

When using the shielding gas, ensure all connections are tight and there are no leaks. The higher flow rate is not always the better. 15-20 CFH is ideal for indoors, but you can increase it if there is a draft or wind. Using too high rates for a given application can create turbulence that sucks in contamination instead of forcing it away from the welds.

Adjust the Right Flow Rate before Welding

Source: https://www.nexair.com/learning-center/what-is-the-ideal-gas-pressure-for-mig-welding/

8. Practice the technique

Laying your first-ever weld can be a disappointing experience, but don't get demoralized. Mastering the art of welding and, most importantly, perfecting the technique takes time, practice, and patience.

Source: https://www.youtube.com/watch?v=LWuWkfZD1yE&t=259s

To start, you should consider the most important technique factors:

-

Arc length

-

Travel speed

-

Travel angle

-

Electrode manipulation

Arc length is the distance from the tip of the electrode to the surface of the joint or base metal. Staying too close to the base metal can cause the electrode to stick, or burn through the pieces. Moving your torch too far from the base metal will extinguish the arc or cause excessive spatter.

Travel speed denotes how fast you are going across the joint. Going too fast can cause a lack of fusion since you don't spend enough time melting filler and base metal. Traveling too slowly will create extensive heat, and cause burn-through.

Source: https://www.youtube.com/watch?v=GNDf13LTZps

The angle of your torch or gun can also impact the performance. Most welding is done at a 10-15-degree travel angle, as it provides proper heat and filler metal distribution while allowing you to see and control a weld puddle.

Electrode manipulation explains how you move the electrode across the joint. For beginners, we recommend going in a straight line or stringer beads. These are great for thin and medium-thickness metal. But for large joints and thick metals, you should consider weaving.

Stringer Bead vs. Weave Bead in Stick Welding

Source: https://www.youtube.com/watch?v=4yssYl2T1z4&t=604s

9. Play with the puddle

Finding the sweet spot between all the parameters mentioned above can be time-consuming but highly rewarding. Consistency is crucial, so you will need some time to practice. As you practice, do not be afraid to play with the puddle.

Practice leading the puddle without trying to weld metals. Try going faster or slower than you did in the previous run, or add or reduce a few amps and observe the results. The perfect weld bead is uniform across its length, without discoloration, holes, or interruptions. You shouldn't settle for less, although small mistakes won't affect the structural integrity of the weld.

Good Welds

Photo by @Amazing Engineering (Linkedin)

10. Get comfortable when welding

Welding can be a physically demanding occupation that involves working in harsh conditions. Exposing your body daily to uncomfortable positions can create repetitive strain injuries.

Luckily, as a hobby or home welder, you can deal with repetitive strain injuries by working in comfortable positions. Use lifts and tables to bring low work to your level. Store your tools close to you so you can grab them without reaching for them.

Support for your hands or arms during the welding. Proper support will allow you to move the torch with precise control and less effort and strain. You can even use specific support bars to rest wrists, forearms, or elbows during the welding.

Get a Comfortable Position when Welding

Source: https://www.youtube.com/watch?v=gooDyq1bAbs

11. Clean and store everything after you weld

Leaving your workplace clean and clutter-free creates a safe welding environment. After your work, make sure you clean the debris and store your equipment properly.

Debris, cables, and mess can cause injuries in the garage or workshop. In addition, flammable substances such as oil or fuel can cause fire, so make sure your environment is hazard-free before and after you finish welding.

Properly store your equipment. Keep your welder away from dust, metallic particles, and moisture, as they can greatly reduce the working hours. More importantly, store filler rods in humidity-controlled conditions. Electrodes and filler rods can pick up moisture, creating inconsistent results and poor arc performance.

Clean and Store Everything after Welding

Source: https://www.reddit.com/r/Welding/comments/

Practice is a Crucial Part Of Welding

Reading our practical tips for welding beginners is important, but nothing beats hands-on experience. So, after everything sets in, grab your torch and start welding.

Remember the safety and welding preparation to create ideal conditions for welding. Understand your equipment and how it can work with the metal you are about to weld.

Find a sweet spot in welding parameters and a technique for consistent results and uniform welds. Play with the puddle and stay comfortable to avoid long-term injuries and fatigue. Finally, clean and store everything in the workshop to bypass clutter and hazards.

🧐Welding Tips For Beginners And New Welders FAQ

- Use lifts and tables to bring low work to a comfortable level.

- Store tools within easy reach to avoid overreaching.

- Provide proper support for your hands or arms to reduce strain.

- How To Choose The Right Welding Types

- Welding Salary Trends: How Much Do Welders Earn Today?

- How To Choose the Right Gas For Welding Different Metals

Leave a comment