Welding Safety For New Welders And Beginners

Welding is a magnificent but reasonably complex profession that takes practice, time, and patience. As a new welder, you must consider many things, so you might wonder where to start. Whether you're exploring welding as a hobby or a budding profession, prioritizing safety is the key to unlocking the full potential of this versatile craft.

In this guide, we delve into the essential principles of welding safety for new welders and beginners. From understanding the importance of protective gear to navigating potential hazards, we'll equip you with the knowledge to weld confidently and securely.

Importance Of Welding Safety

Safety is paramount in welding due to the inherent risks associated with the process. The welding arc produces extreme temperatures, intense light, and potentially harmful fumes, sparks, and spatter. High temperatures and sparks can cause burns or start a fire and explosions in your shop or garage, while intense radiation can damage your eyes and skin.

Welding also includes welding in uncomfortable positions with an increased risk of strain and injuries. In addition, welding or a cutting arc can produce high noise, potentially damaging your hearing. Electric arc processes can also cause electric shock, so keeping yourself safe and wearing protective equipment is essential.

Even though this might sound concerning or discouraging to you as a new welder, understanding where dangers come from and following the safety precautions will ensure years of safe welding. That's why we'll start our article by getting familiar with welding hazards.

Welding Safety Hazards To Avoid

The first step in keeping yourself safe as a new welder is understanding where hazards come from.

Welding involves various hazards that pose risks to the health and safety, and common welding hazards include:

- Welding Fumes and Gases

- Arc Radiation

- Electric Shock

- Burns

- Fire and Explosion

- Noise Exposure

- Eye And Vision Damage

- Vibration and Repetitive Motion

Awareness, proper training, and adherence to safety protocols are essential to mitigate these welding shop safety hazards and ensure a safe working environment in welding operations. As a beginner, you'll first need to know the background of these hazards, so we'll start by briefly explaining why and how each occurs.

Source: https://www.allaboutpiping.com/welding-hazards-and-control-measures/

Welding Fumes And Gases

Welding fumes are produced once the temperature of an arc heats the base metal or consumables (welding rods and electrodes) above their melting point. The fume consists of very fine particulates containing various potentially harmful metals, including aluminum, beryllium, arsenic, manganese, and lead. Additionally, fumes and gases can form once you weld through paint or a protective layer of zinc or oxides. In rare cases, shielding gases such as argon, carbon dioxide, and carbon monoxide can cause poisoning when welding for longer periods in confined spaces.

As a result, welding fumes and gases can cause both acute and chronic illnesses. Short-term exposure to harmful fumes can cause acute irritations, metal fume fever, or acute pneumonia. However, long-term exposure to fumes can cause occupational asthma or lung cancer, so wearing protective equipment such as a respirator and ensuring proper ventilation or a local exhaust system is essential.

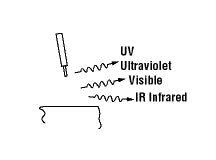

Arc Radiation

The welding arc produces intense visible, ultraviolet, and infrared radiation. Exposure to arc radiation can cause damage to your eyes and skin. Firstly, looking with a bare eye at the arc will produce an injury to the surface and mucous membrane (conjunctiva) of the eye called "arc eye," "welders' eye," or "arc flash." It can cause a series of uncomfortable symptoms such as photosensitivity, pain, sand in the eye feeling, and more.

What is an arc eye?

Source: https://blog.radwell.com/what-is-welding-arc-flash

Since it produces radiation similar to sunlight, direct exposure to arc radiation can burn your skin. The radiation can burn it directly or bounce off metal, walls, and other structures. Long-term exposure to radiation can even cause skin cancer, so it is essential to wear heat and radiation protection in terms of welding hoods and goggles, wear eye and face protection, and make sure you dress for the job and cover the skin.

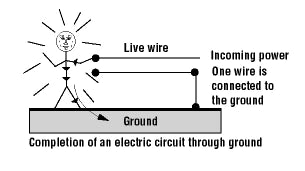

Electrical Shock

Most welding processes for beginners, such as MIG, TIG, or Stick welding, are electrical arc processes, which means they use electricity to form an arc. The electricity circles around the closed circuit between your welder, grounded base metal, and electrode, and if you close the bridge between the welding supply and return, you can get shocked.

Source: https://www.ccohs.ca/oshanswers/safety_haz/welding/electric.html

The most common shocks occur once you simultaneously touch the electrode while leaning on a grounded table or base metal (secondary shock), and these are usually not life-threatening. Meanwhile, you can get electrocuted when touching internal parts or input power (primary sock), so it is essential to take precautions against electrocution.

Burns, Fires And Explosions

The welding arc reaches exceptionally high temperatures that melt the pieces and filler material and fuse them. However, those high temperatures can cause burns, fires, and explosions in your shop. High amperage processes, such as Stick welding, can create lots of sparks and spatter (molten metal particles) that fly around your workshop or garage.

Flying sparks can land on your skin and cause severe burns. Additionally, the proximity and radiation can burn any unprotected skin. If you weld in a garage, sparks can get into oil or gas stains, causing fire or even explosions. That's why welders must wear flame-resistant clothing and ensure no flammable materials are in the working area.

Noise Exposure

Welding and plasma-cutting procedures generate significant noise levels, typically between 85 to 110 decibels (dBA) and 90 to 120 dBA. While noise levels can depend on the specific process, activities such as carbon arc welding and gouging, pulsed TIG welding, high-frequency welding, grinding, and sanding can produce noise that can eventually damage your hearing.

Short-term noise exposure will cause acute hearing issues, but long-term exposure can cause permanent hearing damage. Wear ear protection such as plugs or cuffs when working with high-noise processes to avoid it.

Eye And Vision Damage

Long-term exposure to welding arc radiation can cause permanent eye and vision damage, but you can also injure your eyes during welding preparation. Debris and spatter can easily get into your eyes, so wear safety glasses, face shields, or other eye protection even when not welding. Keeping your eyes protected is crucial to retiring as a healthy welder who keeps his vision even after the harshest work.

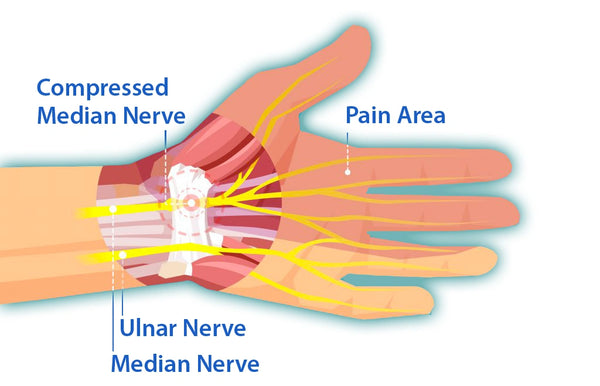

Vibrations And Repetitive Motion

Welders do the same things over and over again every day. This sort of repetitive motion can lead to injuries like carpal tunnel syndrome. Other repetitive strain injuries include tendinopathy, bursitis, and tennis elbow.

In addition, prolonged exposure to vibration transmitted from tools to the body can damage the blood vessels, nerves, and tendons in the fingers, hand, and wrist. Once these conditions take hold, they are irreversible, so it is essential to protect welders from prolonged exposure.

Personal Protective Equipment (PPE) For Beginners

Most of the hazards listed above, such as burns, shocks, radiation, and fumes, can be avoided if you wear the right PPE (Personal Protective Equipment). As a new welder, you shouldn't even consider starting welding before getting the right tools and equipment that will keep you safe. So, let's start from the head to your toes.

Personal Protective Equipment for welders include:

Ear protection: Ear plugs or noise-canceling ear muffs are crucial in protecting your hearing and ears. Plugs will help you during the welding as you can wear them under the hood, while muffs are a great choice when grinding or post-cleaning your welds.

Face Protection: Face protection includes a welding helmet, goggles, glasses, or a face shield, and the choice will depend on your applications.

- A welding helmet is the all-around best choice for beginners since it will keep both hands free, and it also has a grinding mode so that you can use it for multiple applications.

- Goggles are typically used in cutting or oxyacetylene welding where you are not so close to arc heat, while glasses will protect your eyes from debris when grinding.

LYG-R100A Auto Darkening Welding Goggle

- Many old-school welders prefer a face shield, as it was the cheapest and most popular protection back in the day.

Welding Respirator: A welding respirator is a crucial piece of equipment when there is a risk of toxic fume exposure or when welding in confined spaces. You can fit it under your hood or opt for a welding helmet with a built-in respirator to protect your lungs and respiratory system from breathing harmful substances.

Protective Clothing: Protective clothing includes a long-sleeved leather jacket, apron, and gloves. Wearing fire-resistant clothing will protect you from heat, radiation, fire, and burns.

- A leather jacket with long sleeves treated with flame retardants forms a great protective barrier. It is suitable in colder climates and fully protect welders from heat and radiation.

- However, if you are welding in a warm climate, you can opt for a welding apron, which offers better cooling and air circulation and prevents heat buildup. It will protect you from metal spatter, high heat, and radiation, but without protecting your hands.

- Leather gloves will protect your hands from the heat and radiation of the arc. But they still need to provide enough dexterity to allow you to manipulate the torch and filler metal.

AP-1166 Heat Resistant Welding Gloves

Welding Boots: Welding boots must protect against heat, sparks, and other welding-related hazards. Most of them are steel-toed shoes to protect your feet from injuries, leather shoes provide good dexterity, slip-resistant shoes are great when working in harsh conditions, and electrical hazard shoes will provide electrical shock protection.

Welding Safety Tips and Guidelines For New Welders And Beginners

Prioritizing safety in welding is crucial to protect the well-being of the welder, prevent accidents, and maintain a secure work environment. Adhering to safety measures and using proper protective equipment are fundamental practices for anyone involved in welding activities.

Now that you are aware of the hazards and know what kind of protective equipment you need, it is time to learn some welding safety tips and guidelines that will keep you safe during welding operations.

1. Read The Manual First

Before assembling your new welder and starting welding, take your time to read the manual and familiarize yourself with it. Each machine is built differently in terms of required power, polarity, setup, operation, and more, so take your time. Failing to connect or start a welder properly can trip your breakers, you can get shocked, or you'll have lots of spatter and inconsistent arc during the welding, which can be dangerous.

In addition, every product used by welders has a corresponding Material Safety Data Sheet (MSDS). A product's MSDS describes potential dangers, necessary precautions, and exposure limits, so make sure you read it before actually using the product.

2. Take A Welding Course

If you are an absolute beginner, a decision to train for a career in welding will significantly help you understand the crucial welding techniques, as well as enforce safety procedures. Choose a trade school that prepares students for further challenges and potential hazards, as most successful and experienced welders know safety is paramount. So, learning how to protect yourself from fumes, shocks, and radiation is as important as learning how to wield your torch.

Also, you can check the welding safety guidelines provided by reputable organizations designed to protect welders. Organizations such as the National Ag Safety Database (NASD), Occupational Safety And Health Organization (OSHA), National Institute for Occupational Safety & Health (NIOSH), and more have a complete list of safety rules to follow.

3. Cover The Skin

Shorts and T-shirts have no place in a welding workshop. Exposed skin is susceptible to ultraviolet and infrared rays' painful and damaging effects. Additionally, sparks catch in open pockets, pant cuffs, or down a shirt that isn’t completely buttoned, and it can be a harrowing experience.

Yes, welding includes high temperatures, so the overall temperatures in the workplace can be a nightmare to work in. However, you can't disregard the welding safety and weld in the harshest conditions. You can find a way to cool down during breaks, but you cannot forget the burn marks on your skin. That's why you should always wear flame-resistant clothing, such as denim pants and a shirt made from tightly woven material.

4. Wear The Right Protective Equipment

The list of personal protective equipment welders must wear is extensive, but welding safety is about learning what's the best in the given situations. There are various types of welding helmets, gloves, jackets, etc., and your primary goal is to find equipment that provides enough protection, comfort, and agility to help you work comfortably and express your skills.

Source: https://www.aws.org/

For example, Stick welding is done at high amperage, which means high temperatures, so you'll need thicker clothes and a welding helmet with higher shades. Meanwhile, TIG welding is often used in low-amp applications and requires perfect hand coordination, so you can use lighter gloves and clothes that promote dexterity. MIG welding is placed somewhere in the middle so that you can take a more universal approach.

5. Clean And Declutter Your Workplace

Your workspace should only contain the tools and equipment you’re using for that specific project. A welder and other tools come with leads, gas hoses, cables, and more, which can create huge clutter in your workplace. As you move, you can tangle the cords or even trip on them, so it is crucial to ensure you can move freely around your workshop.

In addition, sparks and spatter can easily cause fire or explosions in the workplace. Any leftover puddles of oil or gasoline in your garage or unprotected gas cylinders are potential fire hazards, so ensure your workplace is also clean.

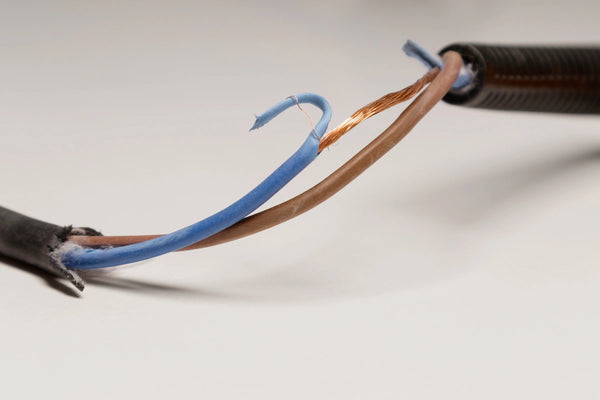

6. Check Your Equipment

Equipment inspection and maintenance are crucial in ensuring a safe welding environment. Even though it will take some experience to maintain your welder properly, you can spot frayed wires or leaking hoses even as a beginner. These are never a good sign, and you should replace them to avoid the risk of an electric shock or gas leaks, which can poison you or cause a fire hazard.

Once you develop your welding skills, you'll be able to check each part of your welder, including the torch, wiring, wire feed mechanism, and internal components. However, as a new welder, a simple visual inspection before welding will do just fine.

7. Protect Yourself From Harmful Gases

Burning the metal with the heat of an arc can create various harmful gases such as nitrogen, carbon dioxide, argon, carbon monoxide, hydrogen fluoride, etc. As a beginner, you are likely to weld in your garage or workshop, so it is crucial to protect yourself from exposure. The easiest way to do it is to provide proper ventilation or a good draft. That way, harmful gases are blown away by natural air circulation.

However, things can get tricky if you weld in confined places or there isn't good ventilation in the shop. Harmful gases, or even shielding gas, can build and cause severe damage to your lungs and respiratory system. In that case, you must wear a welding respirator or use a local exhaust system.

8. Fire Prevention

As we noted, sparks and hot spatter can fly all around the workshop, so it is crucial to think about fire prevention. That's why you must wear flame-resistant outerwear gloves and ensure enough emergency exits, fire extinguishers, sand buckets, and other fire protection measures. Even a simple mistake or oversight can create a fire in a shop that can be hard to put out when everything lights up.

Source: https://www.canadianmetalworking.com/

9. Avoid Stress Injuries

Repetitive stress injuries (RSIs) in welding, also known as musculoskeletal disorders (MSDs) or cumulative trauma disorders, are conditions that result from repetitive motions, prolonged periods of awkward positions, or continuous exposure to vibration. Welders are susceptible to RSIs due to the nature of their work, which often involves repetitive tasks and extended periods of time in specific postures.

To avoid repetitive stress injuries, make sure you take occasional breaks and use them to stretch and allow your body to rest. Repetitive stress will build up damage to your tissue and muscles, which can be highly unpleasant in the future.

10. Adapt To Safety Precautions

Knowing the welding safety precautions and rules differs from adapting and following them. New welders tend to drift away from the safety programs after a brief flurry of initial activity. That's why you should incorporate safety into daily work habits. Spending a few more minutes daily checking your welder, workplace, and personal equipment can significantly impact the overall welding safety for beginners.

Source: https://safetyculture.com/topics/welding-safety/10-welding-safety-rules/

Final Thoughts

Mastering the art of welding is an exciting journey filled with creative potential, but it must be undertaken with a steadfast commitment to safety. That's why our guide has illuminated the critical importance of prioritizing safety for new welders venturing into the world of welding.

From safeguarding against the invisible threats of welding fumes to donning the protective armor of appropriate gear, each safety facet is a weld in the foundation of a secure and fulfilling welding experience. Adopting the welding safety tips, rules, and guidelines will ensure years of safe welding.

🧐Welding Safety For New Welders And Beginners FAQ

1. What are common welding hazards?

Welding involves various hazards that pose risks to the health and safety, and common welding hazards include:

Vibration and Repetitive Motion

2. Why is personal protective equipment for welders critical?

Personal protective equipment (PPE) for welders is critical because it helps prevent burns, shocks, radiation exposure, and fume inhalation. Prioritizing safety in welding is essential to protect the welder's well-being, prevent accidents, and maintain a secure work environment. Using the right PPE is fundamental for anyone involved in welding activities, as it provides necessary protection and comfort, allowing welders to work confidently and efficiently.

👏 You may be interested in the following:

- How To Stick Weld

- Welding Positions Explained

- Welding Arc Eye Injury Prevention - Welding Safety Tips

Leave a comment