Understanding Automated Welding and Future Trends

Welding evolves from manual, straightforward operation into a specialized, automated process. Welding automation utilizes specialized equipment and tools to automate welding tasks and potentially replace welders.

Automated welding provides various advantages, such as higher efficiency, improved quality, and precision. As the machines do all the hard work, the process is safer, and it reduces the number of operators needed to perform the tasks.

Understanding automated welding and its fundamentals is crucial in making the right choice and following future trends. So, let's learn more about welding automation, its benefits, and its applications.

Automated Robotic Welding

Source: https://www.robots.com/articles/buying-a-robotic-welding-system

What is Automated Welding?

Automated welding is a process that uses specialized equipment, robots, fixtures, and software to enhance the welding process. Machines work together to increase the productivity, safety, speed, consistency, and quality of the weld with minimal operator intervention.

Modern automation includes automating the entire process. Machines load, position, and unload parts, and robotic arms weld the pieces. Common types of welding automation include robotic welding, automated welding cells, and automated welding machines.

-

Welding robots are very precise. They move smoothly and at considerable speed along a programmed path. Sensors follow the seam, monitor welding parameters, and apply corrections if needed.

-

Automated welding cells are self-contained units that automate the welding process, typically using robotic arms and welding equipment.

-

Automated welding machines use mechanical, electrical, and computerized controls. They range from simple devices that automate specific welding functions to complex robotic systems used in mass production.

Automated welding is highly customizable. With minimal human interference, you can create systems that perfectly suit your needs and applications. The most efficient automated welding systems are tailored to your needs.

Source: https://joinerservices.io/everything-you-need-to-know-about-welding-automation/

Brief History of Automated Welding

The first semi-automatic welding machines emerged in the 1930s. They featured an automatic wire feeder that improved efficiency and reduced labor. Later, during the war, the need for faster production led to the development of the first automated process—Submerged Arc Welding (SAW).

Submerged Arc Welding (SAW) Process

Source: https://fractory.com/submerged-arc-welding-explained/?trk=organization_guest_main-feed-card_feed-article-content

However, the welding automation we know today arose in the 1960s. In 1961, Unimation introduced the first industrial robot (Unimate), which scientists soon adjusted for welding tasks in automotive production. Today, manufacturers use welding automation in many industries, including aerospace, construction, shipbuilding, and others.

New technologies and technological advancements have made welding robots very precise and fast, allowing them to work at high speeds. Automated welding became ideal for mass production and high-volume welding.

Since the 2010s, smart and adaptive welding systems have been continually evolving. AI, machine learning, and IoT are integrated into welding systems, allowing for predictive maintenance, adaptive welding, and remote monitoring. You can save and share the data and get feedback or real-time suggestions from artificial intelligence.

Smart Welding Station System Concept

Source: https://www.researchgate.net/figure/The-smart-welding-station-system-concept_fig3_338411058

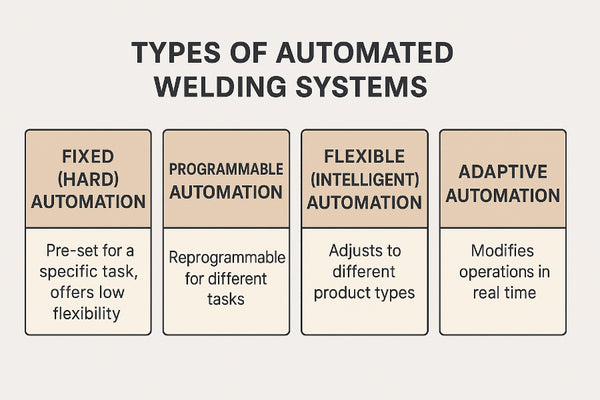

Types of Welding Automation

We can divide welding automation into different types based on the level of automation, flexibility, and scope of application. The most common types of automated welding systems are:

-

Fixed (Hard) Automation

-

Programmable Automation

-

Flexible (Intelligent) Automation

-

Adaptive Automation Systems

Each has its ups and downs, so let's explain them further.

Fixed (Hard) Automation

Fixed, often called hard automation systems, are tailored for mass production on single, repetitive tasks. The welding process is entirely automated, so the machines do all the hard work to produce a single product or part.

These systems use custom-built fixtures and machines that are not easily reprogrammable. Typical examples of hard automation include spot welding in automotive assembly lines or Submerged arc welding (SAW) in pipeline production.

The most significant advantage of fixed automation is its efficiency in mass production, with minimal operator involvement. The machines handle the parts and produce fast, repetitive, and high-quality welds.

However, fixed automation is often costly. Systems that require custom engineering have a high initial cost and cannot be reprogrammed or adjusted to perform different tasks.

Car Body Spot Welding on an Automotive Production Line

Source: https://www.twi-global.com/technical-knowledge/faqs/what-is-spot-welding

Programmable Welding Automation

Programmable automation uses programmable systems, such as robotic arms or CNC-based welding machines. By altering software or settings, you can reconfigure them for different welding tasks or parts.

In programmable welding automation, welding is semi-automated. This principle provides medium-to-high flexibility to produce a variety of products or parts. It requires moderate setup time between different jobs, and it is ideal for batch production and varied product lines.

Typical examples of programmable welding automation include robotic MIG or TIG welding in metal fabrication. Manufacturers often use it in production lines where components vary slightly in shape or size. The equipment is less expensive compared to fixed automation, but reprogramming the software requires higher operator skills.

Robotic MIG Welding in Programmable Automation

Source: https://blog.hirebotics.com/robotic-welding-programming-best-practices

Flexible Automation

Flexible automation utilizes a semi-automated welding process for low-volume production. The system can work with a variety of products or parts.

The equipment used in flexible automation is generally less expensive than programmable automation. The flexibility comes from the ability to reconfigure the system to produce different parts quickly. As a result, you can perform similar operations on various components and assemblies.

You can see traces of flexible automation in the aerospace and shipbuilding industries for non-uniform or large parts. Manufacturers also use flexible automation for precision welding on medical devices or electronics.

Source: https://www.mwes.com/capabilities/assembly-and-automation/flexible-automation-systems/

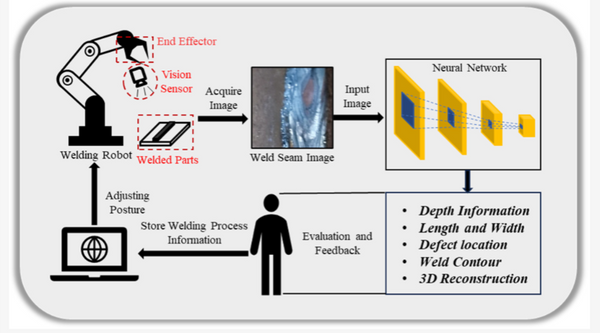

Intelligent Automation

The latest automation systems use a series of sensors, machine vision, and AI to make real-time decisions. Due to real-life feedback, machines and robots adapt to part misalignment, dimensional variation, or changes in the work environment.

In a nutshell, intelligent automation systems are mostly semi-flexible or flexible. Nevertheless, the introduction of modern technologies allows them to improve welding results and the quality and consistency of the welding process.

High adaptability and precision are ideal for complex geometries or low-volume, high-mix production. Intelligent automation systems can improve the quality and consistency of the welding process.

The introduction of advanced sensors, machine vision, and artificial intelligence makes equipment more expensive. However, increased quality and precision reduce the need for rework and cut the overall welding costs.

Source: https://community.automationedge.com/t/enterprise-intelligent-automation-reasons-to-implement-it/11066

Parts of Welding Automation Systems

An automated welding system typically consists of several standard components that work together to perform precise, consistent welds with minimal human intervention. The standard parts of welding automation systems are the following:

-

Welding Power Source

-

Welding Robots

-

Positioners, Manipulators, and Fixtures

-

Software

-

Sensors and Machine Vision

-

Human-machine Interface

-

Optional add-ons

Below is a breakdown of the main parts and useful add-ons.

Source: https://www.researchgate.net/figure/The-structure-of-the-robot-welding-system_fig2_350335434

Welding Power Source

A welding power source supplies the necessary current and voltage for welding. Automated systems can work with various welding processes, such as MIG welding, TIG welding, Stick/Arc welding, Laser welding, or Plasma Arc welding.

The power source, or welding machine, features the most common welding parameters for amperage (wire feed speed), voltage, pulse, laser width (laser welding), or shielding gas flow. Overall, the power source is similar to regular welding processes, but its accessories are adjusted to work with robotic arms or torch manipulators.

Source: https://www.voestalpine.com/welding/global-en/products/product-search/robotic-welding/

Welding Robot

Depending on the type of automation, welding systems utilize a robotic arm or gantry system to perform the weld. Fully automated welding systems often use a six-axis robotic arm. Welding robots comprise a three-axis lower arm and a three-axis wrist. The torch is mounted at the wrist so that it can work in all the positions necessary for three-dimensional welding. Multi-axis robots are perfect for intricate and complex designs.

Torch manipulators or gantry systems are used in semi-automated or large-part applications. The system moves the welding torch in linear or rotational paths to produce repetitive welds. These systems are better suited for straightforward designs and mass production, as they speed up the process and improve precision.

ACS Industries adds gantry robotic welding to build mining and steel buckets.

Source: https://www.metalformingmagazine.com/article/

Positioner, Manipulator, or Fixture

Positioners and manipulators in welding automation move, center, and position the pieces before the weld. These parts hold and manipulate the workpiece in the correct position and orientation. Typical examples of positioners and manipulators in automated welding are rotary tables, headstock-tailstock positioners, and 3-axis or 5-axis manipulators.

Once aligned, the welding robot can weld accurately and efficiently. Systems can also use fixtures if the applications require them. Fixtures hold the workpiece securely in place during welding and ensure dimensional consistency and proper joint alignment.

Source: https://www.researchgate.net/figure/Welding-robotic-station_fig1_223506535

Software and Programming

Software is the brain behind automated welding. The software enables users to create and edit welding programs, set welding parameters, and monitor the welding process. Programming can be manual, where the operator manually inputs the welding path, or offline, where trained personnel program the welding path using CAD models.

The software controls the movement of robotic arms, wire feed speed, arc initiation, travel speed, and more. Welding robots or torch manipulators follow the pre-programmed paths and use the given parameters.

Programming is a crucial part of welding automation. Without proper tailoring and software adjustments, robots are practically useless. On the other hand, users use software to customize the welding process to suit specific welding applications.

Image from Yaskawa Motoman

Human-Machine Interface

The human-machine interface provides a connection between humans and welding robots. Operators use a touchscreen or control panel to control the process, adjust welding parameters, monitor the process, or upload the program.

Advanced machines today often incorporate safety interlocks, diagnostics, and data logging capabilities. These are the intelligent parts of communication between the operator and the machine. Meanwhile, simple systems use straightforward, drag-and-drop interfaces.

Source: https://www.kuka.com/en-de/products/robot-systems/software/planning-project-engineering-service-safety/

Smart Sensors

The latest automated welding systems feature smart sensors and cameras to monitor the weld. Sensors check for misalignment and monitor the critical welding parameters, such as arc length, voltage drops, or lack of current. Some systems also feature a camera, so you can visually check the quality of the weld on the go.

Advanced sensors provide seam tracking, part detection, or adaptive control. Intelligent systems can sense abnormalities and make real-time adjustments. Smart algorithms and digital interactions allow for more intelligent decision-making and customization in manufacturing operations.

Source: https://www.mdpi.com/1424-8220/23/24/9700

Optional Add-ons

The major pro of welding automation is the ability to customize and adapt the system to your welding applications. If necessary, manufacturers can integrate various systems to enhance the safety and productivity of the operation. Let's see some examples.

-

Cooling unit: Adding or improving the cooling system increases productivity. Cooling units are mandatory in high-duty cycle applications.

-

Fume extraction system: Extracting fumes from the workplace improves environmental safety. It reduces the risk of toxic fume exposure to operators.

-

Quality control system: Automated weld inspection tools can monitor and check the quality of the weld. Poor parts are discarded or sent for rework.

-

Safety enclosure or light curtain: Often seen in compact, desktop robotic systems, safety enclosures protect operators from arc light, sparks, and possible injuries.

Source: https://uk.linkedin.com/in/navamagesh-chandrasekar-1bb032128

These add-ons are mostly optional, but they can significantly improve the safety, efficiency, or quality of automated welding.

Advantages of Automated Welding

Automated welding offers significant benefits for industrial production, particularly in high-volume, mass production. Here's an overview of its advantages:

-

Increased Productivity: Automated systems are faster than manual welders and can operate 24/7 with minimal downtime. Productivity makes it ideal for high-volume and repetitive tasks.

-

Consistent, Repetitive Weld Quality: Automated welding produces uniform, repeatable results and eliminates variability caused by human fatigue or inconsistency. Consistency reduces the chances of defects or rework.

-

Reduced Labor Costs: Once the system is up and running, automated welding uses fewer skilled welders. One operator can often supervise multiple computerized stations, reducing the overall labor costs.

-

Improved Worker Safety: Machines do all the hard work, yielding lesser exposure to arc radiation, fumes, heat, and physical strain. Protective measures limit the risk of injury in hazardous environments.

-

Better Material Utilization: Intelligent sensing and pre-programming minimize over-welding and material waste. Exact parameters provide tighter control over wire feed and gas consumption.

-

Real-Time Monitoring and Control: Integrated sensors and software enable real-time adjustments and remote diagnostics. Data collecting enhances process control and traceability.

-

Highly customizable: You can fine-tune and tailor the automated system to fit your needs and welding applications. You can build large, fixed automation systems or add flexibility for different jobs.

Source: https://www.thefabricator.com/tubepipejournal/article/automationrobotics/making-the-move-from-hard-automation-to-robotic-welding

Drawbacks of Welding Automation

Although advantageous, welding automation has some drawbacks that concern its cost justification. Not all jobs can be automated or provide a fast ROI. Here are the most notable disadvantages of welding automation:

-

High Initial Investment: Robotic arms, controllers, vision systems, and integration can be costly. Automating the welding process may not be profitable for small-scale or custom projects.

-

Limited Flexibility (in Fixed Systems): Fixed automation is ideal for repetitive tasks, but struggles with a variety of complex parts. Changing setups can be time-consuming and expensive.

-

Technical Complexity: Although automated welding cuts down labor, skilled technicians are required to program, maintain, and troubleshoot systems. Training or hiring operators can be costly, and downtime due to technical issues can be expensive.

-

Not Ideal for All Welding Scenarios: Some automation types don't work well with complex joints, tight spaces, or artistic welds. Without vision systems, robotic welders may not perform well on dirty, rusty, or misaligned parts.

-

Maintenance and Repair: Automated systems need regular maintenance and occasional recalibration. Breakdowns can require specialized parts or support, leading to longer downtimes.

Source: https://joinerservices.io/everything-you-need-to-know-about-welding-automation/

Applications of Automated Welding

Automated welding is highly beneficial in industries where high volume, precision, or consistency are essential. Below are the most common applications, along with real-life examples.

Automotive Industry

Robotic welders often do spot welding and seam welding on car body panels, frames, and exhaust systems. They produce high-speed, repetitive welds demanding precision and consistency.

Some of the greatest car manufacturers use automated welding. For example, Tesla and Toyota use robotic arms for spot welding and MIG welding in their production lines. Ford's manufacturing plants feature hundreds of welding robots that are assembling vehicle chassis with minimal human input.

Source: https://weldingofwelders.com/robotic-welding-in-the-automotive-industry/

Aerospace Industry

In the aerospace industry, automated systems weld lightweight materials like aluminum and titanium for aircraft structures and engine components. These applications require ultra-high precision and clean welds.

In real life, Boeing uses automated TIG and laser welding for fuselage panels and fuel tanks. Airbus integrates robotic welding cells for titanium parts in landing gear assemblies.

Source: https://www.stylecnc.com/industry-news/3d-robotic-laser-aerospace-welding-machine.html

Shipbuilding and Marine Industry

Shipbuilding and marine industries use submerged arc welding (SAW) and automated MIG welding for hulls, decks, and structural elements. Automated systems can produce large welds on thick plates where manual work is slow and physically demanding.

Real-life examples include Hyundai Heavy Industries, which uses large-scale automated gantry systems to weld ship sections, and Naval shipyards, which employ track-mounted robots to weld bulkheads and compartments.

Shipyard Welding Automation

Source: https://www.inrotech.com/shipbuilding/

Heavy Equipment and Machinery

Automated systems in heavy equipment manufacturing weld frames, buckets, and booms. Construction and agricultural equipment require thick welds and high strength.

For example, Caterpillar and John Deere use robotic welding for tractor frames and excavator components. Positioners and fixtures handle large and heavy parts while welding robots weld them.

Robotic Welding for Excavator Components

Source: https://www.lincolnelectric.com/en/Welding-and-Cutting-Resource-Center/Application-Stories/A

Medical Device Manufacturing

Precise automated welding joins stainless steel and titanium pieces for implants, surgical tools, and diagnostic equipment. Robots can produce accurate, highest-quality sanitary welds that are perfect for medical device manufacturing.

Companies like Stryker and Medtronic use laser and TIG automation to weld bone plates, catheters, and surgical assemblies. Various other companies use robots for precision work in the medical industry.

Robotic Welding Implantable Medical Devices

Source: https://ebindustries.com/welding-implantable-medical-devices/?utm_source=chatgpt.com

Future Trends in Welding Automation

Advancements in robotics, artificial intelligence, digital integration, and the increasing demand for precision, productivity, and flexibility are shaping the future of welding automation, which is expected to play a significant role in the future of manufacturing.

We will discuss the expected advancements in welding automation below.

Source: https://builtworlds.com/news/learning-from-our-industry-peers-evolutions-in-ai/

Artificial Intelligence (AI) and Machine Learning

Advancements in robotics and artificial intelligence should lead to the development of more advanced welding robots. Adaptive welding systems will learn from real-time data to adjust parameters automatically (e.g., torch speed, arc length).

AI-driven defect detection and predictive maintenance will reduce downtime and improve weld quality. Some advanced systems already feature AI and machine learning, and we will undoubtedly see more of it in the future.

Source: https://www.unboxindustry.com/blog/69-ai-and-machine-learning-powering-of-industrial-automation

Smart Sensing, Vision Systems, and Seam Tracking

Robotic and automated welding systems monitor welds using smart sensors. Moreover, the development of 3D vision and laser-based sensors will enable better joint tracking, even on complex or misaligned parts.

Improvements in sensor technology will yield Real-time correction for irregularities in joint fit-up or material thickness. These improvements will enhance the reliability and quality of the welds, reducing the need for rework or wasted material.

Source: https://www.sciencedirect.com/science/article/abs/pii/S0263224118305463

Internet of Things (IoT) and Industry 4.0 Integration

Industry 4.0 and the integration of IoT will play a key role in the development of smart factories. Welding systems are becoming a part of connected factories, enabling remote monitoring and diagnostics, data-driven process optimization, and cloud-based performance analytics.

As the robots weld, all data is uploaded and monitored. Intelligent systems and operators can perform data and performance analytics and tailor the parameters. Adjusting the parameters can improve efficiency, reduce costs, and increase productivity.

Integration of Welding IoT for Smart Manufacturing

Source: https://resources.arcmachines.com/integrating-welding-iot-into-smart-factories-ami/xcdxwqsaq

Low-Code and No-Code Programming

Programming welding robots can be challenging for many, so they have to rely on experts. New automation trends bring easier programming interfaces that will allow non-experts to configure welding robots quickly.

Drag-and-drop or teach-pendant-based tools will make automation accessible to smaller shops. They wouldn't need to hire more personnel and experts to program the machine.

Source: https://www.fanucamerica.com/solutions/applications/welding-robots/cobot-welding-package-systems

Customization, Flexibility, and 3D Printing

We are seeing increased demand for modular welding automation platforms instead of a traditional, fixed system. Plug-and-play modules and 3D printing will revolutionize the manufacturing industry by enabling the production of complex, customized products on demand.

Faster system upgrades and deployment will enable manufacturers to produce complex, customized products more efficiently. Flexible platforms can be scaled up or down depending on production needs.

Source: https://thgautomation.com/

Collaborative Robots (Cobots)

We are expecting to see more collaborative robots instead of traditional robots. Cobots allow human welders and robots to work side-by-side safely.

Collaborative robots are ideal for low-volume, high-mix production environments where full automation isn't practical. They are easier to program and flexible for small and medium enterprises (SMEs).

Source: https://www.hirebotics.com/welding-cobots

Final Thoughts

Welding automation has revolutionized manufacturing by increasing productivity, improving weld quality, and enhancing workplace safety. From automotive and aerospace to construction and medical device production, automated welding systems offer consistent, efficient solutions for a wide range of applications.

As technology advances, the integration of AI, vision systems, and collaborative robots is making automation more flexible and accessible. While initial costs and technical complexity remain challenges, the long-term benefits in quality, cost savings, and scalability are driving widespread adoption.

🧐Understanding Automated Welding and Future Trends FAQ

-

Fixed (Hard) Automation – Designed for high-volume, repetitive tasks with minimal flexibility.

-

Programmable Automation – Offers reprogrammable control for batch production of varying parts.

-

Flexible (Intelligent) Automation – Uses advanced technologies to adapt to real-time changes in the welding environment and product design.

Leave a comment