Puddle Recognition Tips For TIG Welders

Successfully recognizing weld puddle issues is necessary to make quality TIG welds. But, it's just as important to recognize when you are welding correctly. That way, you can reinforce good techniques and avoid issues in the future.

In this article, you'll learn how to recognize puddle issues when TIG welding, if you are running too hot or too cold of an arc, and some tips specific for TIG welding stainless steel and aluminum.

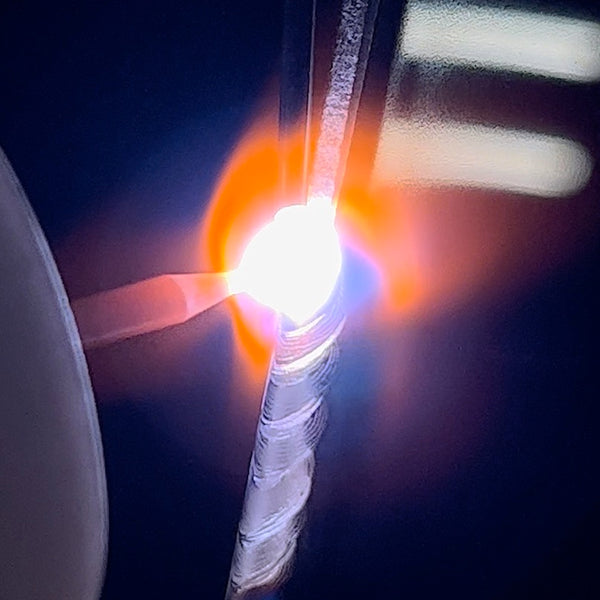

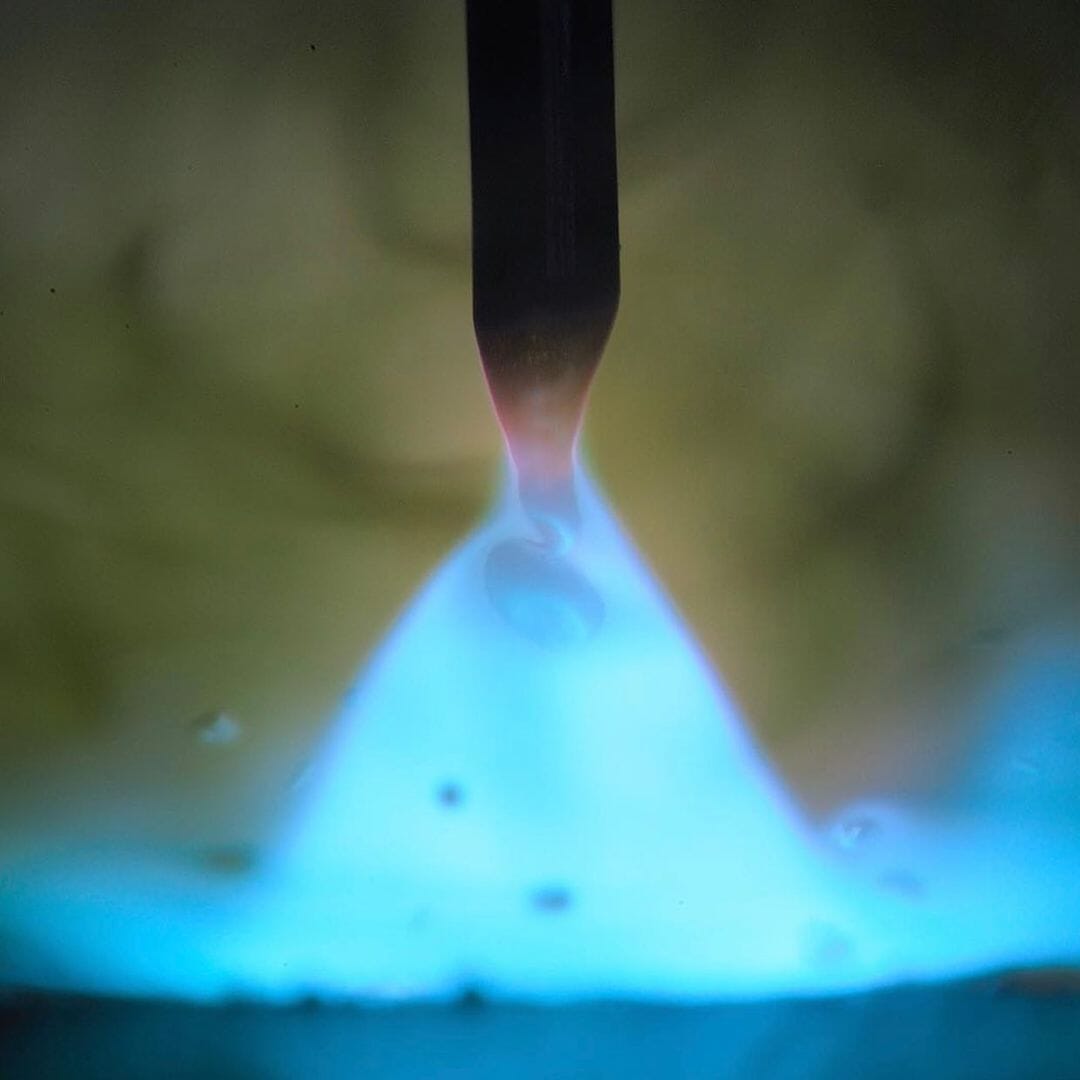

Photo by @twi_ltd

Essential Technique Prerequisites For Proper TIG Welding

- Get a comfortable body position over the welded piece so that you can achieve good hand mobility and stability

- Maintain a smooth torch travel

- Use the correct torch angle for the joint type

- Apply a consistent arc length

- One hand moves the torch; the other feeds the filler material

- Ensure sufficient shielding gas coverage

- Don't dip the tungsten into the weld puddle

- Don't move the filler material outside of the shielding gas zone beneath the cup

- Don't touch the tungsten tip with the filler metal as you weld

- Don't use a thicker filler wire than the welded material

Violating any of the essentials listed above will cause puddle control issues, and reduce, if not outright ruin the weld quality.

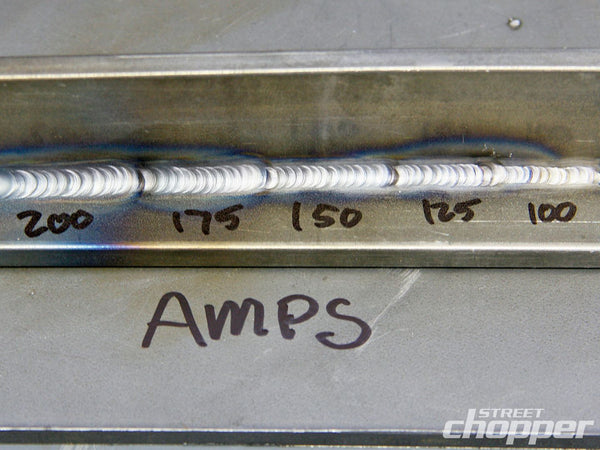

Recognizing The Correct Amperage Input

One of the most common issues welders make is applying too much or too little heat for the material thickness and the travel speed. This is guaranteed to cause either poor penetration or warping and burning through on thinner metal.

Luckily, you can prevent these issues by reading the puddle and recognizing if you need to back off the amperage or increase it.

Source: https://www.motorcyclecruiser.com/story/tips-and-tech/tech-tig-welding-steel-101/

Weld Puddle Is Too Hot

If your TIG welder is set to output too high amperage for the welded material thickness, you will experience the following issues:

- Shaky puddle - It's okay to experience a little bit of an unsteady and wobbly molten puddle surface. But, if your weld puddle is too shaky and experiences high trembles, it won't be easy to direct and control.

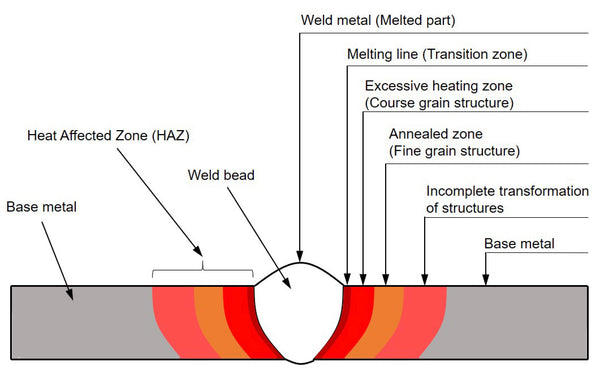

- Too wide heat affected zone - Inputting too much heat when TIG welding causes a wide HAZ. As a result, you are risking warping and oxidation damaging the welded material (especially on stainless steel).

Source: http://www.difference.minaprem.com/joining/difference-between-weld-metal-and-heat-affected-zone-haz/

- Oxides buildup in the weld pool - You may also experience oxides building up in the weld pool depending on your shielding gas coverage and travel speed.

- Weld pool pulls contaminants into itself - If you didn't clean the material upfront properly, running your TIG welder too hot will pull more mill scale into the weld pool and other contaminants.

- Undercut - Using too high amperage will cause undercutting, especially when making a fillet weld. High heat will erode the upper part of the fillet joint and cause undercutting, which weakens the weld.

Source: https://weldguru.com/undercut-in-welding/

- Puddle is melting through - If the puddle falls through the edges of the joint, you are definitely using too many amps.

Weld Puddle Is Too Cold

Beginner TIG welders are often afraid of warping and burning through the thin material. So, it's a common mistake to use too low amperage. However, this fear is rational. It's easy to burn through and distort thin sheet metal, especially stainless steel.

It takes some trial and error to figure out the correct amperage. The signs below indicate that you have reduced amperage output too much and that increasing it will help:

Photo by @twi_ltd

- Forming the weld puddle is too slow - If the base metal melts too slowly, you are doing more harm than good by concentrating the arc into one spot for a prolonged period.

- Filler material won't melt in the weld puddle - If you dab the filler wire into the weld puddle and it won't fully melt, increasing amperage output may help.

- Poor puddle fluidity - Unlike the shaky, wobbly puddle made with too much heat, the low heat input will create a small puddle that barely consumes the base metal and moves slowly.

- Poor penetration - Using too low amperage output results in poor joint penetration and fusion, making a weak bond.

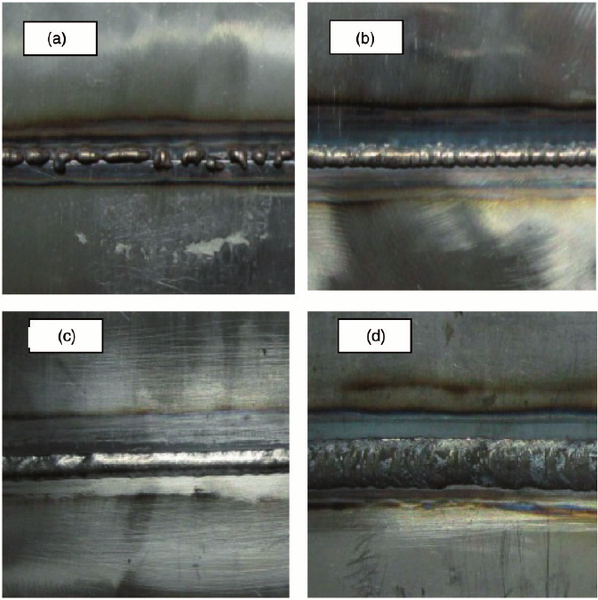

Weld configuration of (a) incomplete fusion, (b) lack of penetration (c) sound weld (d) excessive penetration/over burn.

Source: https://www.researchgate.net/figure/Weld-configuration-of-a-incomplete-fusion-b-lack-of-penetration-c-sound-weld-d_fig2_277360289

Puddle When Welding Dirty Material

If you don't clean the material properly from mill scale, oxides, paint, oils, and other contaminants, you are unlikely to achieve a quality TIG weld.

Some of the signs that your material needs more cleaning are:

- Debris forming on the solidifying weld puddle

- Porosity in solidified weld

Source: https://www.youtube.com/watch?v=Vfhz9anpaWE

- Bubbles in the molten weld pool

- Smoke coming off from the weld puddle

- Uneven ripples of the TIG welds even if you tried your best to space them out evenly

- Poor, brittle welds after they solidify

Source: https://weldingpros.net/arc-weld-troubleshooting/

Stainless Steel

Most puddle recognition tips we discussed so far apply to all metals. But you should know some additional things about stainless steel and aluminum.

Stainless steel is a poor heat conductor. As a result, it retains heat very well. But, it also tends to oxidize and go through the process called carbide precipitation if the material is held at high heat for prolonged periods.

So, stainless steel gets increasingly hot as you weld because it doesn't dissipate heat like mild steel. But, this concentrated heat tends to oxidize the weld and destroy its corrosion resistance.

This is why it's paramount to control heat input when welding stainless steel. The weld puddle shouldn't be more liquid than necessary, and the HAZ should be as narrow as possible. Use a sharp tungsten tip and ensure good shielding gas coverage.

Additionally, avoid heat concentration in one area for too long. High welding speed is preferred, so don't use too low heat input either. The puddle must be fluid but not too runny. On the other hand, using a too low heat input won't let you weld quickly and avoid high heat concentration in the joint.

You can learn everything about TIG welding stainless steel in our article here.

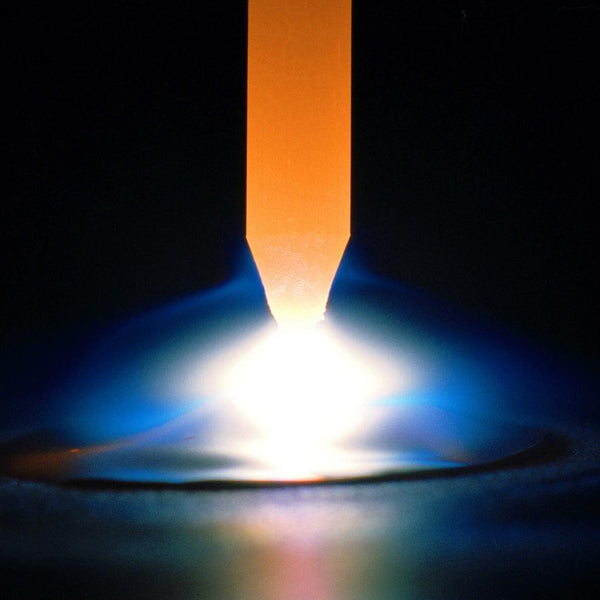

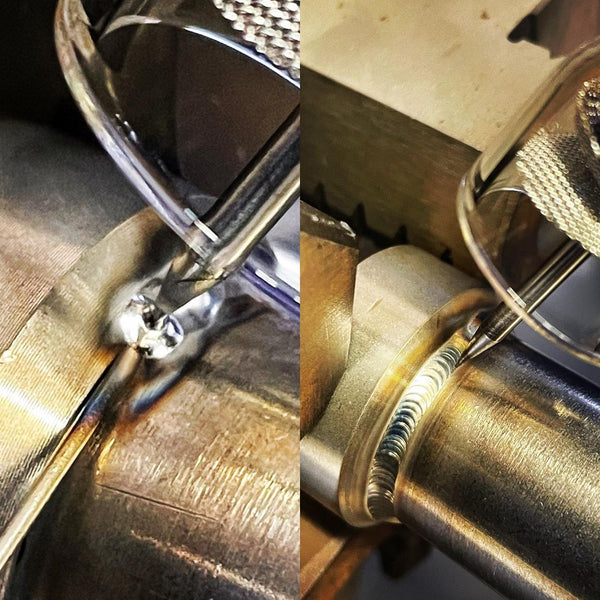

Photo by @castle_ironworks

Aluminum

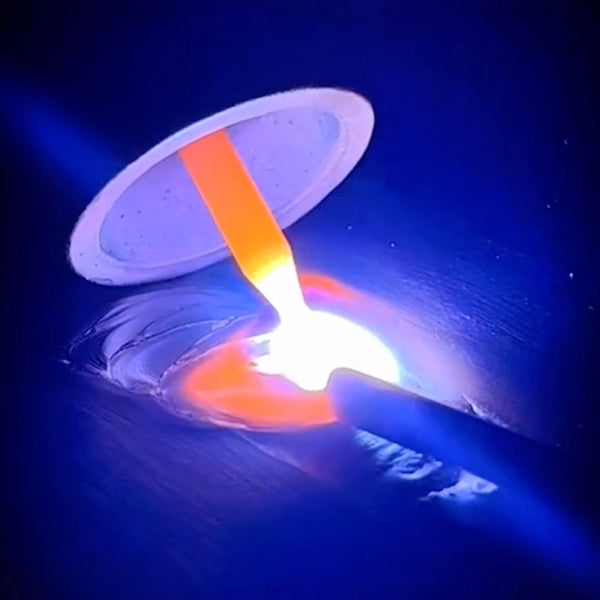

Aluminum is a notoriously difficult material to weld, thanks to its oxide layer. But, this metal has another issue: excessive heat conductivity. So, unlike stainless steel, aluminum is very good at dissipating heat.

To weld aluminum, you need to use a much higher amperage than to weld stainless steel. Otherwise, the puddle will be unresponsive and not liquid enough. That's because the aluminum will dissipate the heat input from the arc into the HAZ and surrounding metal, and there won't be enough power left to keep the weld puddle liquid.

However, as aluminum gets hotter, you may need to back off the foot pedal to reduce the amperage input. If the puddle turns too wide and becomes uncontrollable, reduce the power input.

Photo by @srkwelderboi

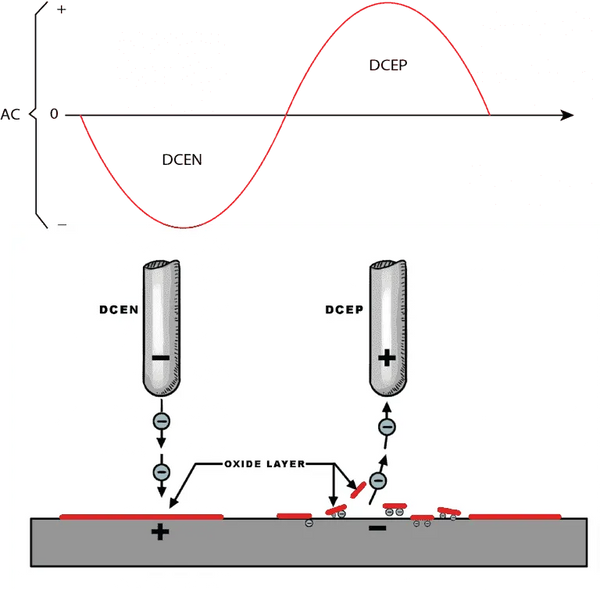

Aluminum Oxides

You must use an AC TIG welder to weld aluminum because the DCEP part of the current is responsible for cleaning the aluminum oxides on the surface. The other part, DCEN, achieves the necessary penetration, melts the material, and fuses the two pieces together.

Source: https://www.materialwelding.com/how-to-clean-aluminum-oxide-layer-before-welding-easy-steps/

However, it's important not to start adding the filler wire and moving the torch until the DCEP cleans the initial puddle. When you initiate the high-frequency arc, you need to wait for a brief moment until the puddle looks like a shiny dot, and only then start moving the torch and adding the filler material.

The initial puddle becomes shiny because the DCEP has burned the oxide, and now the pure aluminum underneath is ready to be bonded with the filler metal.

If your AC balance setting is too shallow, the DCEP won't have much cleaning power. This can result in more oxide inclusion in the weld and make a poor joint. Keep an eye out for any debris floating in the molten aluminum puddle.

Photo by @carpwelding

Use a High-Quality Welding Helmet

To successfully see the puddle issues we previously described, you'll need to use a welding helmet that transmits an adequate amount of color and light.

You should use a helmet like the YesWelder Q800D-A, for example. The true-color technology and 1/1/1/2 optical clarity rating provide excellent visibility over the weld puddle.

Conclusion

The TIG welding process is more challenging to master than MIG or stick welding. And one of the reasons why is the need to efficiently recognize puddle issues in real-time. Sure, it's important to observe the puddle when MIG or stick welding too, but it's also hard to do so. Stick welding creates too much smoke, and the MIG nozzle obstructs the weld view.

Considering how sophisticated TIG welding is, there isn't much room for error. If the puddle is acting up, it's a sign that you need to find the issue and fix it. It takes some time to learn how to properly TIG weld and develop the necessary muscle memory.

But, once you master the heat input control, the travel speed, and the puddle cues, you'll make fantastic TIG welds and be able to perform the most challenging welding jobs.

Leave a comment